Zip Chain Actuator: Complete Guide for Industrial Automation

A Zip Chain Actuator is an innovative linear actuator designed to deliver precise, smooth, and reliable motion in compact industrial systems. Using a retractable chain mechanism, it converts rotary motion into linear movement, making it perfect for applications where space is limited but performance cannot be compromised.

In this blog, you’ll get a complete guide to Zip Chain Actuators — including how they work, their main components, key features and benefits, typical applications, advantages over other actuators, selection tips, and maintenance best practices. By the end of this article, you’ll have all the information you need to understand, select, and use Zip Chain Actuators effectively in your automation or industrial projects.

How Zip Chain Actuators Work

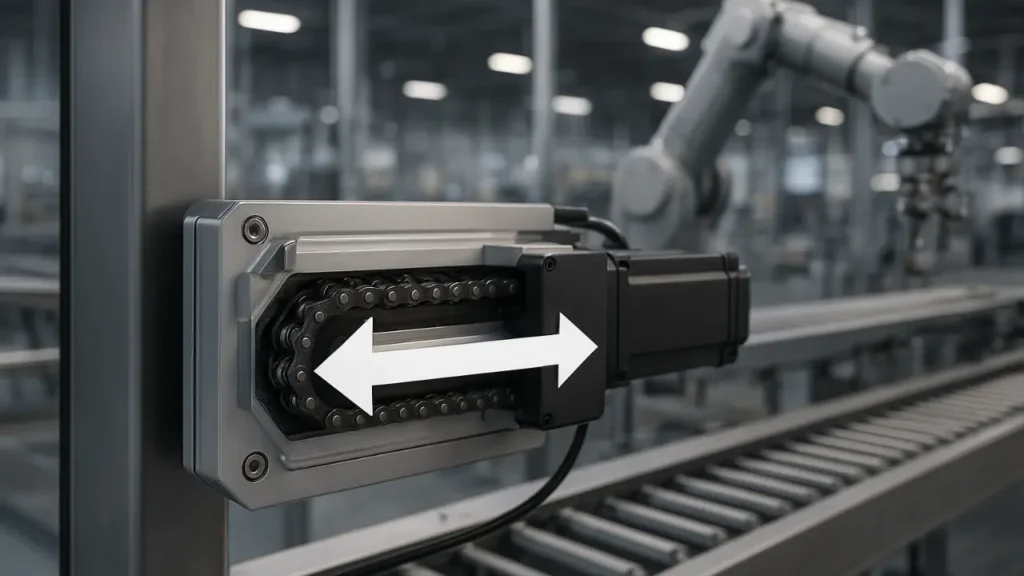

A Zip Chain Actuator uses a series of small chain links that “zip” together to create precise linear motion. When the motor rotates the sprocket, it pulls the chain forward or backward, producing smooth and controlled movement. This clever design allows the actuator to move heavy loads accurately, even in tight or compact spaces.

Unlike traditional actuators, such as screw or belt types, zip chain actuators are compact, fast, and flexible. They can deliver high-speed motion while maintaining precise positioning, making them ideal for automation, industrial machinery, and applications where space is limited.

The chain is housed inside a protective casing, which keeps it aligned and shields it from dust, debris, and other environmental factors. Optional covers or motor assemblies further improve durability and reduce maintenance, ensuring consistent and reliable operation over time.

Another key advantage of the Zip Chain Actuator is its adaptability. The retractable chain allows for a long stroke relative to the actuator’s compact size, while also absorbing shocks and vibrations. This reduces stress on connected machinery, improves performance, and extends the lifespan of both the actuator and the equipment it powers.

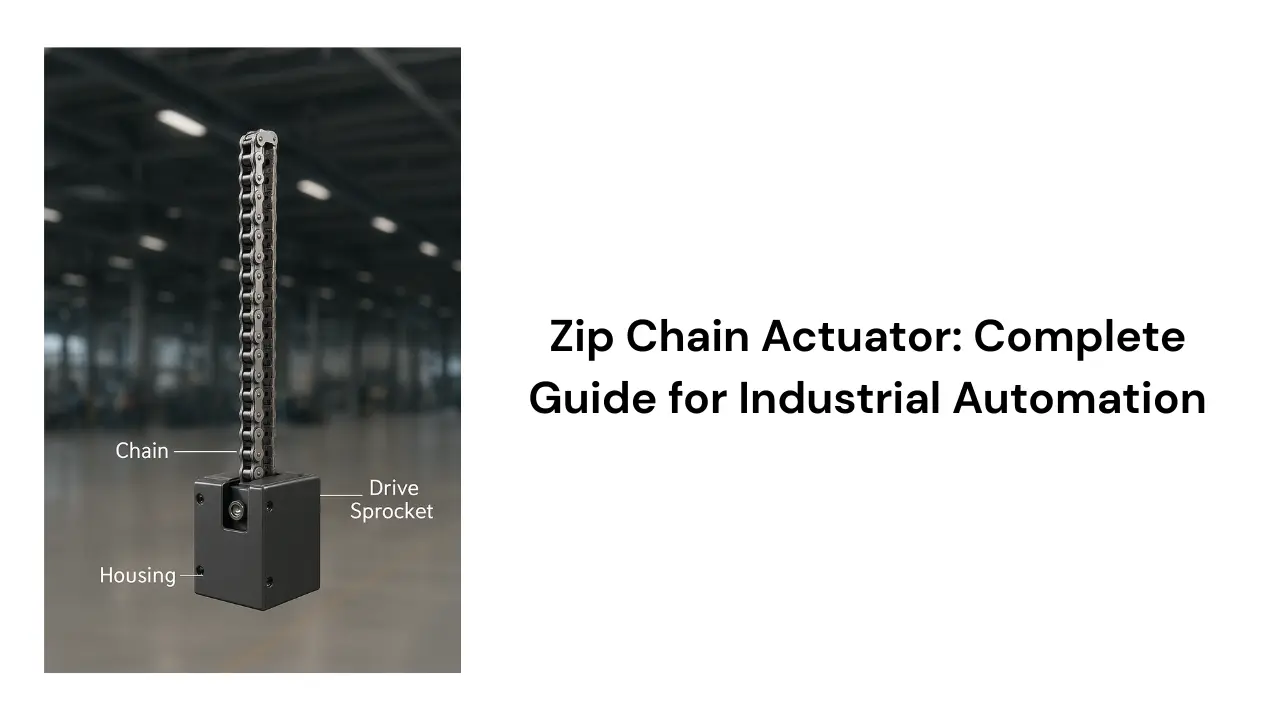

Main Components Explained

The chain segments are the core of a Zip Chain Actuator. These small, strong links connect together and move in a “zip” motion, converting the motor’s rotation into smooth, precise linear movement. This design allows the actuator to handle heavy loads while maintaining accuracy.

The drive sprocket works with the motor to pull the chain forward or backward. It ensures the motion is controlled and consistent, even under heavy or repetitive loads, providing reliable performance in demanding applications.

The housing keeps the chain aligned and protects it from dust, debris, and damage. Many actuators also include optional covers or motor assemblies, which improve durability and simplify maintenance. Together, these components ensure the Zip Chain Actuator operates efficiently, smoothly, and reliably.

Key Features & Benefits

High Load Capacity – Zip Chain Actuators can handle heavy loads smoothly, making them ideal for industrial applications where reliability is critical.

Smooth and Precise Motion – The chain-driven design ensures consistent, accurate linear movement, even under frequent or rapid cycles.

Compact and Space-Saving Design – Unlike traditional actuators, Zip Chain Actuators fit into tight spaces without compromising performance.

Low Maintenance and Long Service Life – With durable chain segments and protected housing, these actuators require minimal upkeep while delivering years of reliable operation.

Adjustable Stroke Lengths – Allows customization of actuator travel to fit different application requirements.

Quick and Easy Installation – Designed for simple setup, reducing downtime during integration into machinery.

Shock and Vibration Resistance – Chain mechanism absorbs shocks, protecting both the actuator and connected equipment.

Energy-Efficient Operation – Uses less energy compared to hydraulic or pneumatic systems, lowering operating costs.

Where Zip Chain Actuators Are Used

Zip Chain Actuators are versatile and can be used wherever precise linear motion is required. Some popular applications include:

- Automated Storage and Retrieval Systems – Moving goods efficiently in warehouses or distribution centers.

- Medical and Laboratory Equipment – Providing smooth and accurate motion for lab instruments or testing machines.

- Theater and Stage Automation – Controlling lifts, platforms, or scenery with precision.

- Custom Industrial Machines – Any machinery that requires compact actuators with high reliability and repeatable motion.

Why Zip Chain Actuators Stand Out

Zip Chain Actuators offer several benefits compared to traditional actuator types, making them an excellent choice for modern industrial and automation systems:

- Space-Saving Design with Precise Motion – Unlike screw or belt actuators, zip chain actuators provide accurate linear movement while occupying minimal space. This is perfect for setups where compactness is essential without compromising functionality.

- Smooth and Consistent Operation – The retractable chain mechanism ensures stable and controlled motion. Even during repetitive cycles or varying loads, the actuator maintains precise speed and positioning, reducing stress on connected equipment.

- Durable Construction for Long Lifespan – Made with strong chain segments and protective housing, these actuators withstand heavy loads and demanding environments. This durability reduces maintenance needs and unexpected downtime.

- Energy-Efficient Design – Compared to hydraulic or pneumatic systems, zip chain actuators consume less energy while delivering dependable linear movement, helping lower operational costs.

- Wide Application Scope – These actuators can manage both light and heavy loads, making them suitable for industrial machinery, automated equipment, stage setups, and laboratory systems.

How to Choose the Right Zip Chain Actuator

Choosing the right Zip Chain Actuator is key to smooth and efficient operation. First, think about the stroke length—how far the actuator needs to extend and retract. Picking the right length ensures precise movement and prevents overload.

Next, consider the load and speed requirements. Make sure the actuator can handle the weight it needs to move while maintaining accurate motion.

The environment also matters. Dust, moisture, or extreme temperatures can affect performance. Some actuators may need protective housings or covers to work reliably in harsh conditions.

Also, pay attention to the duty cycle—how often the actuator will be in motion. Actuators designed for continuous use are built differently than those for occasional movement.

Finally, check the installation space and mounting options. The actuator should fit properly and align with your equipment. By reviewing these points, you can choose a Zip Chain Actuator that works efficiently and lasts longer.

Maintenance and Best Practices

To get the most out of your Zip Chain Actuator, regular maintenance is essential. Keep the chain segments clean and lubricated to ensure smooth motion and reduce wear. Dirt, dust, or debris can cause friction and shorten the actuator’s lifespan.

It’s also important to check the alignment of the chain and sprocket periodically. Misalignment can lead to uneven wear or reduce the efficiency of the actuator. Inspect the housing and covers to make sure they are intact and protecting the internal components.

Replacing worn or damaged chain links promptly is another key practice. This prevents minor issues from turning into bigger problems and ensures the actuator continues to operate reliably. Finally, make sure the motor and other moving parts are free from obstructions and operating smoothly. Following these simple practices can help extend the life of your Zip Chain Actuator and maintain consistent, accurate performance over time.

Conclusion

The Zip Chain Actuator is an innovative solution for applications that need precise, smooth, and reliable linear motion in a compact design. Its retractable chain mechanism makes it ideal for modern automation, industrial machinery, and specialized equipment where space and accuracy are critical.

By understanding how the Zip Chain Actuator works, its main components, key features, and applications, you can make an informed choice for your system. Regular maintenance and proper selection ensure long-lasting, trouble-free performance.

Whether you’re upgrading existing equipment or designing a new system, the Zip Chain Actuator from Ohio Roller Chain delivers efficiency, durability, and precision, making it a smart choice for a wide range of industrial and automation needs.