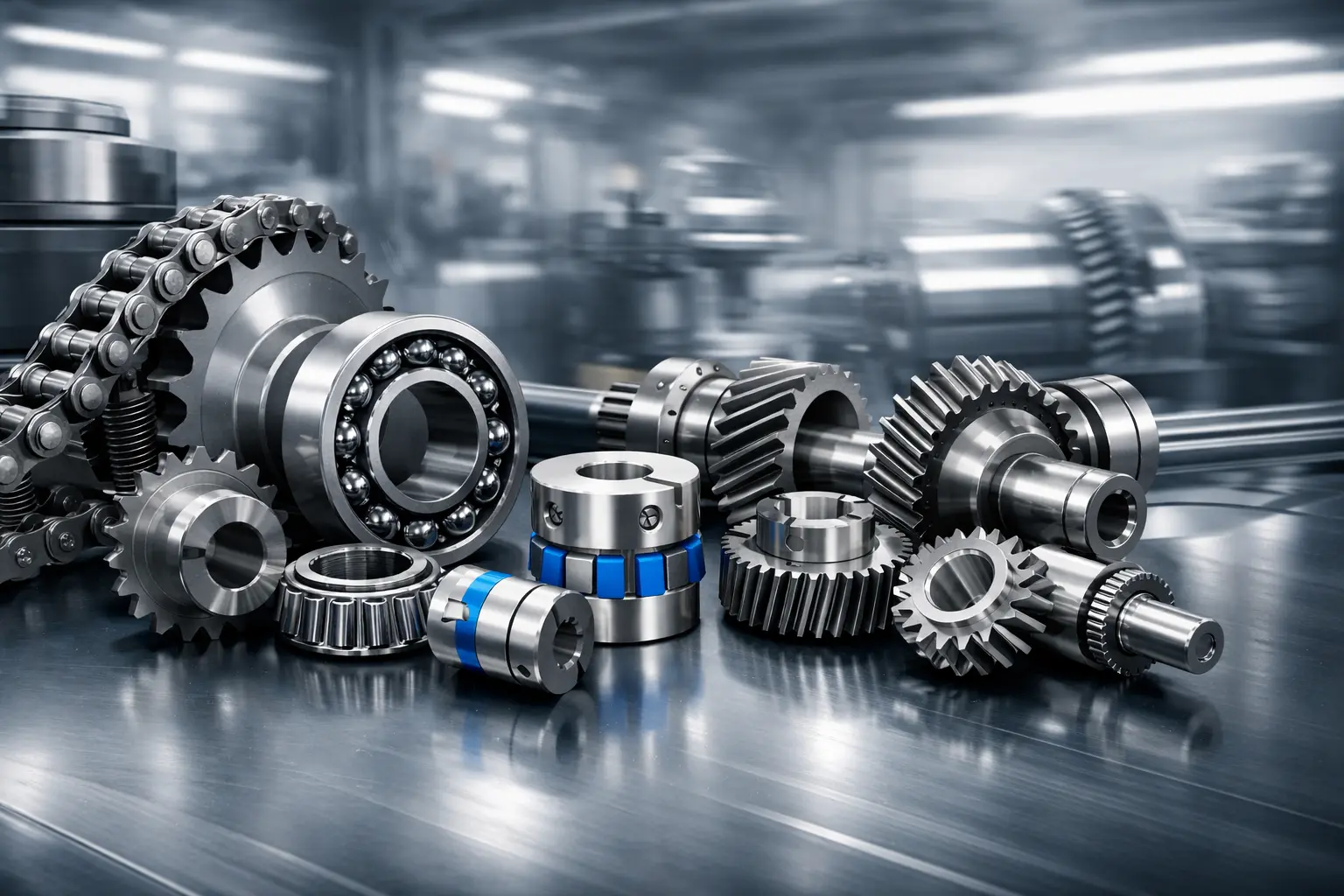

Explore the Wide Range of Products on Ohiorollerchain

Ohiorollerchain is a trusted leader in supplying high-quality industrial transmission components, catering to a wide range of industries, from manufacturing and agriculture to packaging and material handling.

In industrial machinery, the performance and longevity of equipment heavily rely on the quality of its components. Using reliable transmission products ensures smooth operation, minimizes downtime, and extends the overall life of your machines.

At Ohiorollerchain, you’ll find a comprehensive selection of products—including roller chains, sprockets, bearings, couplings, gears, and essential accessories—designed to meet the demands of modern industrial applications.

Whether you’re powering conveyor systems, agricultural machinery, or complex manufacturing equipment, Ohiorollerchain provides durable solutions that keep your operations running efficiently.

What Are Transmission Components?

Transmission components are essential mechanical parts that transfer power and motion from one part of a machine to another. They play a critical role in ensuring that machinery operates smoothly, efficiently, and safely. Without reliable transmission components, machines can experience increased wear, operational inefficiencies, and unexpected downtime.

These components are widely used across various industries. In manufacturing, they power conveyor belts and assembly lines. In agriculture, they drive tractors, harvesters, and irrigation systems. Mining and food processing industries rely on them for heavy-duty machinery, while packaging industries use them to maintain consistent, precise operations. By choosing high-quality transmission components, businesses can optimize performance and reduce costly maintenance issues.

Key Products Available on Ohiorollerchain & Their Uses

3.1 Roller Chains

Description:

Roller chains are robust mechanical chains made of interlinked rollers, designed to transmit power efficiently between rotating shafts. They are a core component in many industrial applications, providing durability, precision, and reliable performance under varying loads.

Uses:

Conveyor systems in factories: Ensure smooth and continuous material movement.

Agricultural machinery (tractors, harvesters): Transmit power for heavy-duty operations.

Material handling systems: Facilitate the movement of goods in warehouses and manufacturing facilities.

Packaging machinery: Enable precise motion for wrapping, filling, and sealing processes.

Types (general):

Single chains: Standard chains for moderate loads and general applications.

Double chains: Designed for heavier loads and increased strength.

Leaf chains: Specialized chains used in lifting applications or high-load industrial equipment.

3.2 Sprockets

Description:

Sprockets are toothed wheels that mesh with roller chains to transmit motion and power between rotating shafts. They are essential in ensuring accurate speed, torque, and direction control in mechanical systems.

Uses:

Drives and conveyors: Provide smooth and efficient movement of materials in industrial settings.

Timing mechanisms in industrial machines: Maintain precise synchronization for machinery operations.

Motorized equipment requiring speed or torque adjustments: Enable flexibility and performance optimization in various mechanical systems.

Types:

Single-strand sprockets: Standard sprockets for single-chain applications.

Double-strand sprockets: Designed for double-chain setups to handle heavier loads.

Custom-designed sprockets: Tailored solutions for specific industrial requirements or unique machinery designs.

3.3 Bearings

Description:

Bearings are critical mechanical components designed to reduce friction between moving parts and provide support for rotating shafts. They ensure smooth, efficient, and reliable operation of machinery while minimizing wear and tear.

Uses:

Motors and gearboxes: Facilitate smooth rotation and maintain alignment of moving parts.

Conveyor rollers: Support continuous movement in material handling systems.

Industrial fans and pumps: Reduce friction and enable efficient operation under varying loads.

Heavy machinery with rotating shafts: Enhance durability and performance in demanding industrial applications.

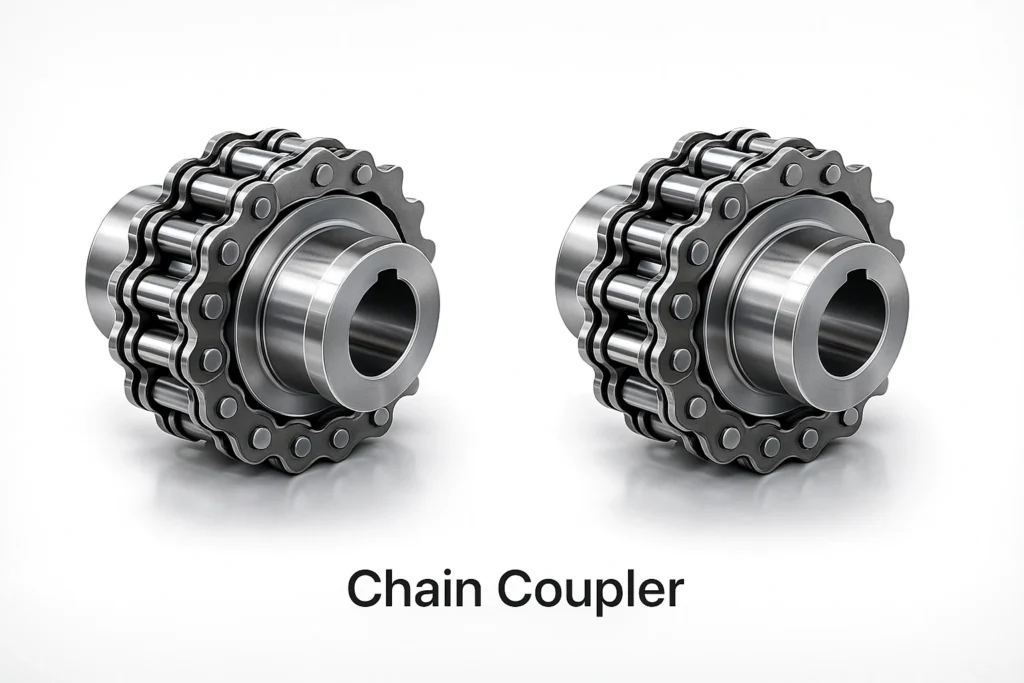

3.4 Couplings

Description:

Couplings are mechanical connectors that link two shafts together to transmit torque while accommodating slight misalignments. They play a crucial role in maintaining smooth and reliable power transmission between connected machinery components.

Uses:

Connects motor to pump, fan, or conveyor system: Ensures seamless transfer of power between driving and driven components.

Reduces misalignment and vibration between connected machinery parts: Protects equipment from undue stress and wear, improving lifespan and efficiency.

Types:

Flexible chain couplings: Allow for minor misalignments and reduce vibration in the system.

Rigid couplings: Provide solid, precise connections where alignment is exact and minimal flexibility is required.

3.5 Gears & Gear Components

Description:

Gears are wheels with teeth that mesh with other gears to transmit motion, change speed, or adjust torque in mechanical systems. They are essential for precise power transmission and efficient operation of industrial machinery.

Uses:

Gearboxes in industrial machinery: Enable smooth speed and torque control in manufacturing equipment.

Elevators and conveyor lifts: Provide reliable movement and load handling.

Automotive and heavy equipment systems: Transmit power efficiently in vehicles and industrial machines.

Types:

Spur gears: Straight-toothed gears for simple, high-efficiency applications.

Helical gears: Angled teeth provide smoother and quieter operation.

Bevel gears: Transfer motion between intersecting shafts at different angles.

Worm gears: Provide high torque with compact design for specialized applications.

3.6 Accessories & Related Components

Description:

Accessories and related components are supplementary parts that support and enhance the performance of main transmission products. They play a vital role in maintaining the efficiency, reliability, and longevity of industrial machinery.

Uses:

Tensioners: Maintain proper chain tension to prevent slippage and reduce wear.

Connectors & fasteners: Secure chains, sprockets, and other transmission parts for stable and safe operation.

Lubrication tools: Ensure smooth and consistent movement by reducing friction and wear between moving components.

How to Choose the Right Transmission Component

Selecting the right transmission component is critical for ensuring the efficiency, reliability, and longevity of your machinery. Here are key factors to consider:

Load capacity: Choose components that can handle the weight and force requirements of your equipment.

Speed: Ensure chains, sprockets, and gears are suitable for the operational speed of your machinery.

Environment: Consider conditions such as temperature, humidity, and exposure to corrosive substances that may affect component performance.

Alignment: Proper alignment of shafts, chains, and gears is essential to reduce wear and prevent mechanical failures.

Tips:

Match chains with the correct sprockets to ensure smooth motion and prevent premature wear.

Select bearings that fit your shafts and load requirements to optimize performance.

By sourcing from a trusted supplier like Ohiorollerchain, you can be confident in the quality, durability, and compatibility of the components, ensuring your industrial systems run smoothly and efficiently.

Why Choose Ohiorollerchain for Transmission Products

High-Quality Components:

All products are manufactured with precision to ensure durability, efficiency, and reliable performance in demanding industrial applications.

Wide Product Range:

Ohiorollerchain offers a comprehensive selection of transmission components, making it a one-stop solution for all your industrial machinery needs.

Expert Guidance:

Knowledgeable staff provide expert advice to help you select the right products for your specific machinery and operational requirements.

Reliable Service:

From on-time delivery to dedicated customer support, Ohiorollerchain ensures that your industrial operations run smoothly with minimal downtime.

Trusted by Industries:

Preferred by clients across manufacturing, agriculture, and other industrial sectors, Ohiorollerchain is recognized for quality, reliability, and professional service.

Conclusion

Choosing the right transmission components is crucial for maintaining the efficiency, reliability, and longevity of your machinery. High-quality chains, sprockets, bearings, couplings, gears, and accessories ensure smooth operation, reduce downtime, and enhance overall performance across industrial applications.

At Ohiorollerchain, you’ll find a comprehensive range of transmission products designed to meet the needs of various industries, backed by expert guidance and reliable service.

Call to Action:

Visit Ohiorollerchain Products to find the right transmission solutions for your business and keep your operations running at peak performance.