The Ultimate Guide to Selecting the Right Roller Chain

The Ultimate Guide to Selecting the Right Roller Chain

Every piece of industrial machinery tells a story of precision, power, and movement. At the heart of that story often lies a deceptively simple component: the roller chain. While it might look like a basic series of links and pins, this mechanism is the backbone of power transmission across the globe. From the engines revving in our cars to the massive conveyors in manufacturing plants, roller chains keep the world moving.

Roller chains are critical because they offer a highly efficient method of transmitting mechanical power. Unlike belts that can slip or gears that require proximity, chains provide a positive, non-slip drive that works over long distances. They are the unsung heroes in industries as diverse as automotive, agriculture, construction, and heavy manufacturing.

However, not all chains are created equal. Selecting the wrong type can lead to catastrophic failures, costly downtime, and safety hazards. Whether you are designing a new conveyor system or replacing a worn-out component on a tractor, understanding the nuances of roller chains is essential.

This guide is designed to help you navigate the complex world of power transmission. We will break down exactly what roller chains are, explore the different types available, and provide a step-by-step framework for choosing the perfect chain for your specific needs.

What Is a Roller Chain?

A roller chain is a type of chain drive most commonly used for the transmission of mechanical power on many kinds of domestic, industrial, and agricultural machinery. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket.

Main Components

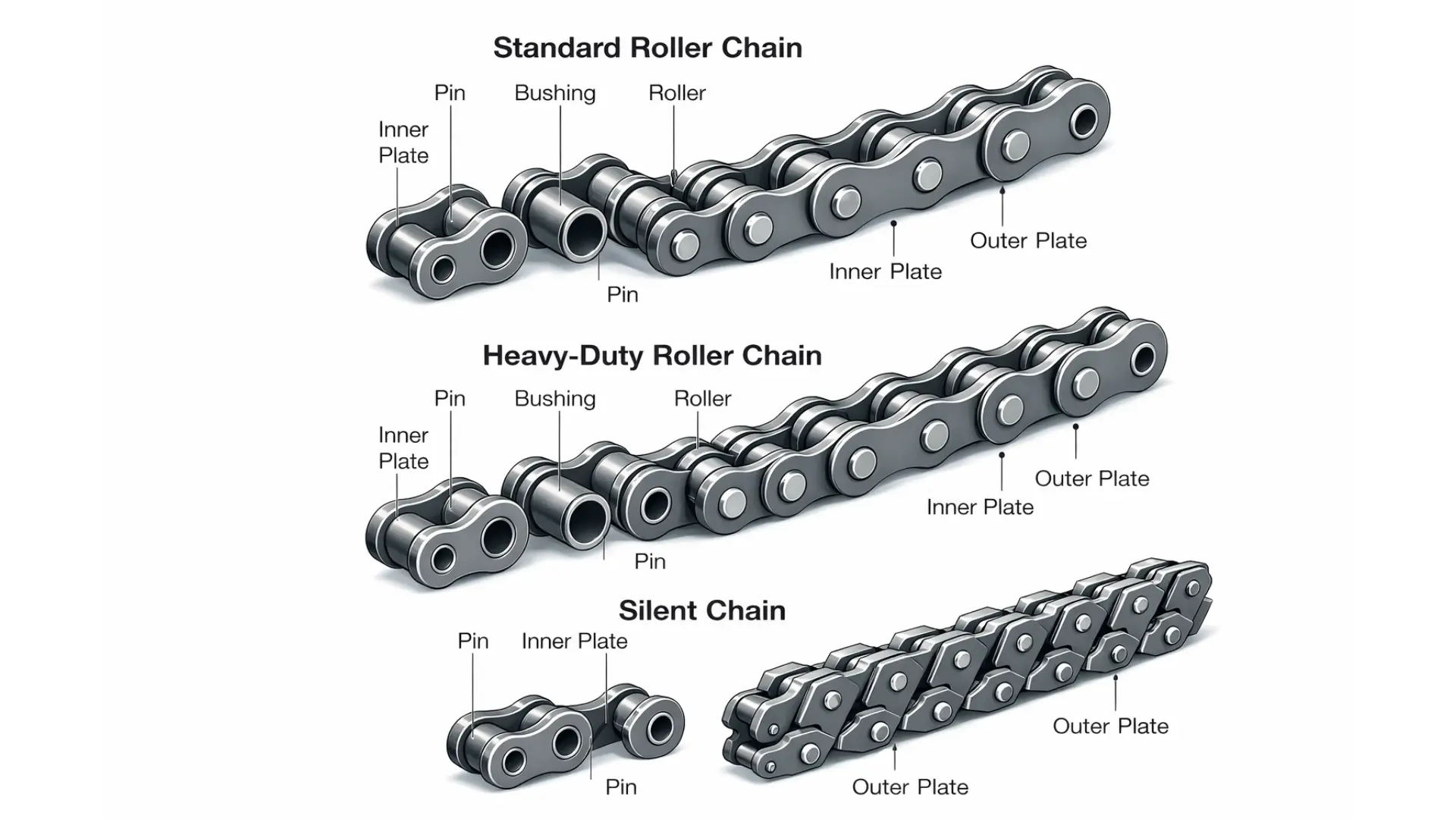

To understand how it works, you need to look at its anatomy. A standard roller chain consists of five basic parts:

- Pin: The axis on which the chain pivots.

- Bushing: A hollow cylinder that sits between the pin and the roller, providing a bearing surface.

- Roller: The free-rotating cylinder that contacts the sprocket teeth.

- Inner Plate: The side plates that form the inner link.

- Outer Plate: The side plates that form the outer link.

How It Works

The primary function of a roller chain is to reduce friction. As the chain engages with the sprocket, the rollers rotate freely on the bushings. This rolling action, rather than sliding friction, significantly reduces wear on both the chain and the sprocket teeth. This design allows for high efficiency—often as high as 98%—making it an ideal choice for transmitting power from a motor to a driven shaft.

Benefits compared to other chains

Compared to simpler bush chains or belt drives, roller chains offer superior durability and wear resistance. Their robust construction allows them to handle shock loads and operate in harsh environments where dust, dirt, or moisture might cause other transmission methods to fail.

Types of Roller Chains

The versatility of roller chains means there is a specialized version for almost every application. Choosing the right type is critical for ensuring efficiency and extending the lifespan of your equipment.

Standard Roller Chains

These are the workhorses of the industry, built to ANSI or ISO standards. They are used in general industrial applications where moderate loads and speeds are expected. If you are running a standard conveyor or a simple drive system, this is likely what you need.

Heavy-Duty Chains

When the going gets tough, heavy-duty chains step in. These feature thicker side plates and sometimes larger pins to withstand higher shock loads and tensile forces. They are essential for demanding environments like mining, logging, or heavy construction.

Silent Chains

Also known as inverted tooth chains, these are designed for high-speed, high-power applications where noise reduction is a priority. The links are shaped to engage with the sprocket teeth smoothly, significantly reducing the noise and vibration typical of standard chains.

Custom and Engineering Chains

Sometimes, off-the-shelf solutions aren’t enough. Engineering chains are designed with specific attachments, unusual dimensions, or unique materials to meet specialized requirements, such as food processing or extreme temperature environments.

How to Choose the Right Roller Chain

Selecting the correct chain involves more than just picking a size off a chart. It requires a systematic approach to ensure compatibility and longevity.

Step 1: Assess Your Application

Start by analyzing the operating conditions. What is the nature of the load? Is the drive running continuously or intermittently? consider the environment—is it abrasive, corrosive, or subject to extreme temperatures?

Step 2: Determine Load & Strength Requirements

Calculate the working load the chain must support. You must also consider the “shock load”—sudden spikes in force that occur during startup or jams. The chain’s tensile strength must exceed these requirements by a safety margin to ensure longevity.

Step 3: Select Correct Size & Pitch

Pitch refers to the distance between the centers of adjacent pins. It is the most important dimension for compatibility. You must match the chain pitch to your sprockets. Refer to ANSI or ISO standard dimension charts to find the appropriate size for your calculated load and speed.

Step 4: Choose Material

Standard carbon steel is sufficient for many applications, but it isn’t the only option.

- Stainless Steel: Best for corrosive environments or food-grade applications.

- Nickel-Plated: Offers some corrosion resistance at a lower cost than stainless.

- High-Temp Steel: Necessary for ovens or furnaces.

Step 5: Check Compliance & Standards

Ensure the chain you select complies with relevant industry standards (like ANSI B29.1 or ISO 606). This guarantees interchangeability and ensures that the chain meets minimum performance criteria.

Common Applications of Roller Chains

You will find roller chains operating behind the scenes in countless sectors.

Automotive

In internal combustion engines, roller chains (specifically timing chains) synchronize the rotation of the crankshaft and camshafts so that the engine’s valves open and close at the proper times during each cylinder’s intake and exhaust strokes. They are also standard on motorcycles for transferring power to the rear wheel.

Industrial Machinery

From assembly lines to packaging plants, roller chains drive conveyors, lifting equipment, and robotic arms. Their ability to maintain precise synchronization makes them indispensable in automation.

Agriculture

Farming equipment takes a beating. Tractors, harvesters, and balers rely on robust chains to drive threshing drums, augers, and elevators, often in muddy and dusty conditions.

Construction Equipment

Cranes, hoists, and cement mixers require chains that can lift massive weights safely. The high tensile strength of heavy-duty roller chains is a non-negotiable requirement here.

Roller Chain Maintenance Tips

Even the highest quality chain will fail prematurely without proper care. A proactive maintenance routine minimizes operational costs and prevents unexpected breakdowns.

Lubrication

This is the single most important factor in chain life. Proper lubrication reduces friction, dissipates heat, and flushes away debris. The oil needs to penetrate the critical gap between the pin and bushing.

Inspection

Regularly inspect your drive system. Look for “stretch” (elongation due to wear), stiff links, or cracked side plates. If the chain has elongated by more than 1.5% to 3%, it is time to replace it.

Cleaning

Dirt and grit act like grinding paste, accelerating wear. Periodically clean the chain with a suitable solvent to remove built-up debris before re-lubricating.

Alignment

Misalignment between the driving and driven sprockets is a common killer of chains. Ensure shafts are parallel and sprockets are in the same plane to prevent side-loading and uneven wear.

Benefits of High-Quality Roller Chains

It might be tempting to cut costs with a cheaper chain, but the initial savings often evaporate when you factor in downtime and replacement frequency.

- Durability: Premium chains use higher-grade steel and advanced heat-treating processes, resisting wear and fatigue much longer.

- Efficiency: High-quality manufacturing ensures precise tolerances, leading to smoother engagement and less power loss.

- Lower Total Cost of Ownership: A chain that lasts twice as long reduces maintenance labor and replacement parts costs.

- Safety: In high-load applications, a cheap chain snapping can be dangerous. Quality chains offer reliability and peace of mind.

Why Choose Us

Navigating the technical specifications of power transmission can be daunting. That is where we come in. We don’t just sell parts; we provide solutions.

- Expert Guidance: Our team has deep technical knowledge to help you select the exact chain for your specific application.

- Wide Range of Products: From standard ANSI chains to specialized silent chains and heavy-duty options, we have it all.

- High-Quality Chains: We stock products that are rigorously tested for performance and reliability.

- Customer Support: We are here to answer your questions and provide recommendations.

Contact our team today to find the perfect roller chain for your machinery.

Our Featured Product: R25 Roller Chain

If you are looking for a versatile, high-performance option, look no further than our R25 Roller Chain.

The R25 is engineered for reliability. It features high load capacity and durable materials designed to withstand rigorous daily use. Its smooth operation makes it an excellent choice for a variety of setups, from intricate industrial machinery and conveyor systems to rugged agricultural and construction equipment.

Get your R25 Roller Chain today and ensure long-lasting, efficient operation of your equipment.

Invest in Reliability

Choosing the right roller chain is about more than just keeping wheels turning; it is about ensuring the efficiency, safety, and longevity of your entire operation. By understanding the types of chains available and following a structured selection process, you can prevent costly downtime and keep your productivity high.

Remember, whether you need a standard replacement or a heavy-duty solution, maintenance and quality matter. Don’t leave your power transmission to chance. With expert advice and high-quality components, you can keep your machinery running smoother for longer.