Role of Power Transmission Components in Industrial Automation

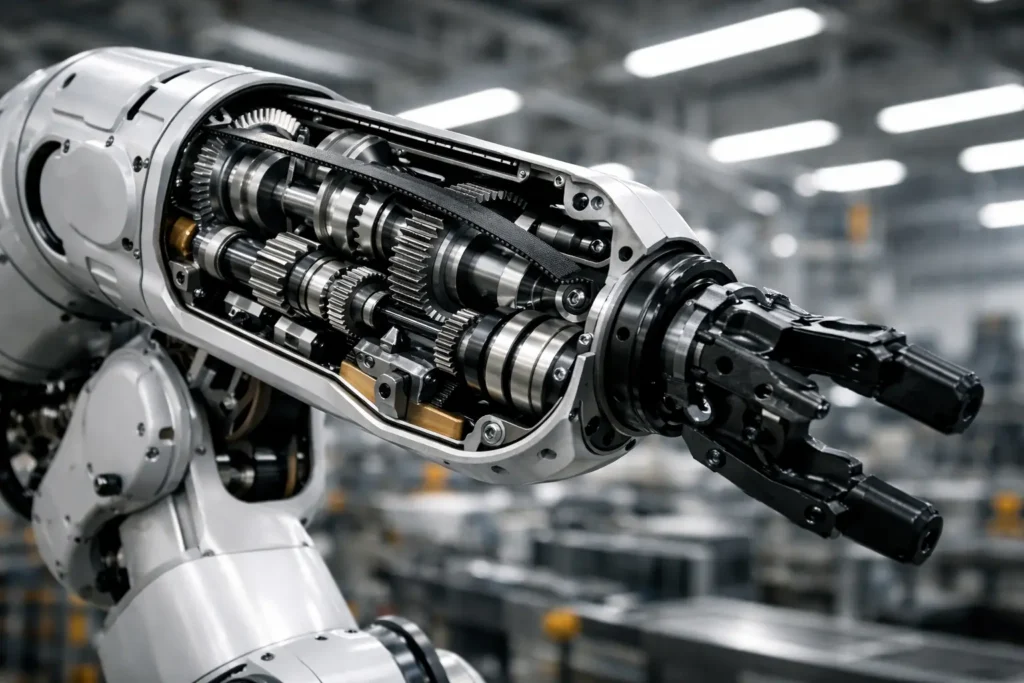

Imagine a modern bottling plant. Thousands of glass bottles clink softly as they glide along a conveyor belt, moving at breakneck speed. A robotic arm descends with surgical precision, filling, capping, and labeling each one in a fraction of a second. It appears to be magic—a seamless blend of technology and efficiency. But strip away the shiny metal casing and the complex software code, and you’ll find the true workhorses of the operation.

Deep inside the machinery, gears mesh, belts whirl, and couplings flex. These components are the unsung heroes of the factory floor. While the software provides the “brains” of the operation, power transmission components provide the “muscle.” Without them, even the most advanced artificial intelligence couldn’t move a single bottle.

This system is the invisible force that keeps modern factories running nonstop. When it works, you don’t notice it. But when it fails, production grinds to a halt, costing thousands of dollars a minute. Understanding the role of power transmission components in industrial automation isn’t just for mechanical engineers; it’s essential for anyone who wants to understand how the modern world is built.

What Happens When Power Transmission Breaks Down?

In the high-stakes world of industrial automation, reliability is everything. A single failed bearing or a snapped belt might seem like a minor mechanical issue, but the ripple effects are catastrophic.

Consider an automotive assembly line. If the main drive chain snaps, the entire line stops. Welding robots pause, paint sprayers idle, and workers stand by. The cost of downtime in the automotive industry can exceed $20,000 per minute. That one small failure translates into a massive production loss in the blink of an eye.

Downtime caused by poor-quality or poorly maintained industrial power transmission components is one of the biggest threats to profitability. Automation depends entirely on smooth power flow. If energy cannot be transferred efficiently from the motor to the machine, precision is lost, timing drifts, and eventually, the system fails.

Power Transmission Explained in Simple Terms

At its core, power transmission is about moving energy from where it is generated to where it is needed to perform work.

Think of a bicycle. Your legs generate the power (the motor). But that power needs to get to the rear wheel to move the bike forward. The chain, the sprockets, and the pedals are the transmission system. They take the raw energy from your muscles and convert it into forward motion.

In industrial automation, the concept is the same, though the scale and complexity differ. An electric motor generates rotational energy. However, that motor might be spinning too fast, or it might be located five feet away from the conveyor belt it needs to drive.

The role of mechanical systems in industrial automation is to bridge that gap. They modify the speed, increase the torque (turning force), and change the direction of that energy, delivering it precisely where it’s needed to lift a heavy load or spin a delicate fan.

Why Power Transmission Is Critical for Industrial Automation

You cannot have automation without motion control. Whether it’s a robotic arm assembling microchips or a giant crane moving steel beams, movement must be precise.

Precise Motion Control

In automated systems, “close enough” is not good enough. A packaging machine needs to stop the conveyor at the exact millimeter to apply a label correctly. High-quality power transmission components ensure that when the motor stops, the load stops instantly, without slipping or shuddering.

Speed and Torque Management

Motors love to spin fast, but most industrial applications need torque (strength) rather than raw speed. A gearbox is essential here. It reduces the speed of the motor while multiplying its strength, allowing a small motor to move a heavy conveyor belt laden with rocks or steel.

Energy Efficiency and Safety

Inefficient components generate heat and noise, which is essentially wasted energy. Premium belts and well-lubricated bearings minimize friction, ensuring that electricity is used to move the product, not heat up the factory floor. Furthermore, reliable components prevent catastrophic failures that could endanger human operators.

Essential Power Transmission Components Used in Automation

Every machine requires a different “recipe” of components to function. Here are the core ingredients that keep automated systems moving.

Gears – Controlling Speed and Torque

Gears are the backbone of industrial power transmission. By interlocking teeth between two wheels, they provide a positive, non-slip drive. In robotics and CNC machines, precision gears are vital. They allow a robotic arm to move with incredible accuracy, ensuring that a weld seam is perfect or a bolt is tightened to the exact specification.

Couplings – Protecting Motors

Motors and the machines they drive are rarely perfectly aligned. If you connect them rigidly, the vibration will destroy the bearings in hours. Couplings act as the handshake between the motor and the load. They accommodate slight misalignments and absorb shock loads, protecting expensive equipment from damage and extending the life of the entire system.

Belts & Pulleys – Flexible Power Transmission

For applications requiring smooth, quiet operation, belts are the go-to solution. Unlike gears, they don’t require lubrication. Timing belts, which have teeth that mesh with the pulley, are essential in packaging automation where timing is critical. They are lightweight, efficient, and capable of high speeds.

Chains & Sprockets – Heavy-Duty Performance

When the environment gets tough—think dust, heat, or heavy loads—chains outshine belts. You’ll see chains and sprockets in palletizers, heavy conveyors, and agricultural machinery. They provide robust power transmission that won’t slip, even under immense torque.

Bearings – Precision Support

Bearings reduce friction between moving parts. Without them, metal would grind against metal, seizing up almost instantly. In automated machinery, high-precision bearings ensure that shafts spin smoothly and quietly, minimizing energy loss and maintenance needs.

How Power Transmission Components Work Together

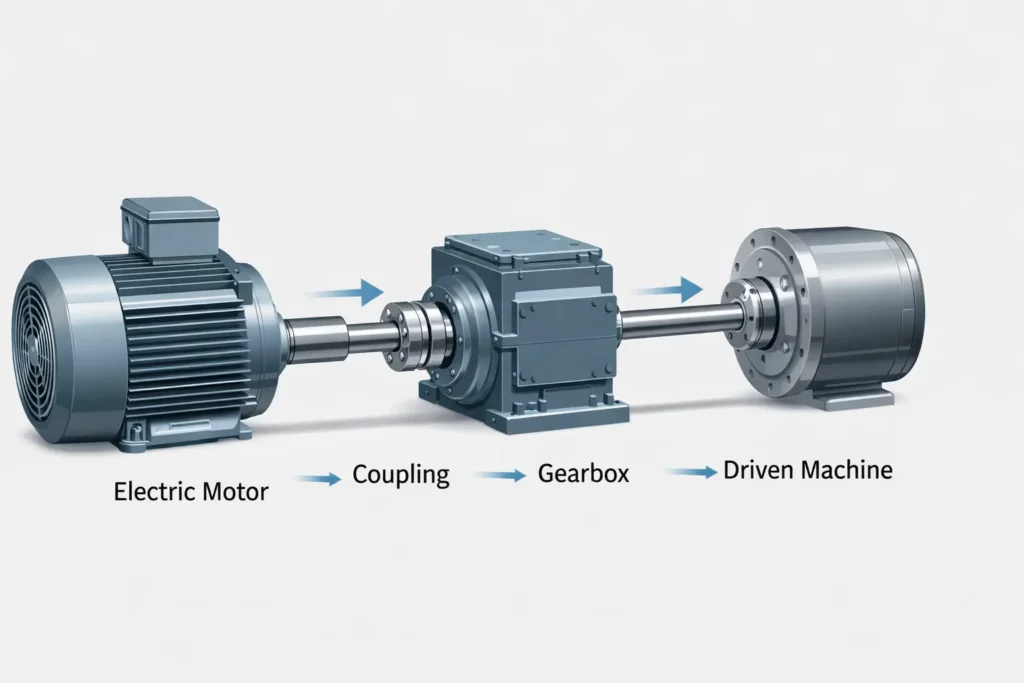

It is rare to find these components working in isolation. They function as an ecosystem. Let’s trace the power flow in a typical automated conveyor system:

- The Source: The electric motor begins to spin.

- The Connection: The motor shaft is connected to a gearbox via a coupling, which absorbs the initial shock of startup.

- The Conversion: Inside the gearbox, gears reduce the high speed of the motor and increase the torque.

- The Transfer: The output shaft of the gearbox features a sprocket, which drives a chain.

- The Movement: This chain turns the roller of the conveyor belt, which is supported by bearings to ensure it spins freely.

If any single link in this chain fails—if the bearing seizes or the coupling cracks—the entire system stops.

Real-World Applications of Industrial Power Transmission

The versatility of these components allows them to be used across every sector of the economy.

- Automated Manufacturing Lines: From bottling soda to assembling smartphones, transmission components ensure precise timing and speed control.

- Robotics: Pick-and-place robots rely on zero-backlash gears to move with pinpoint accuracy.

- Material Handling: Warehouses use miles of conveyors driven by belts and rollers to sort packages for shipping.

- Heavy Industry: In power plants and mines, massive gearboxes and heavy-duty chains move tons of material daily.

Choosing the Right Components for Automation

Selecting the right component isn’t just about fit; it’s about function and environment.

Load, Speed, and Torque

Engineers must calculate the exact requirements. A system moving feathers needs different components than one moving bricks. Using a component rated for a lower load than required is a recipe for disaster, while over-specifying wastes money and energy.

Environmental Factors

Is the machine in a freezer? Is it in a bakery surrounded by flour dust? Is it underwater? Heat, moisture, and contaminants dictate the materials used. Stainless steel chains or sealed bearings might be necessary to prevent corrosion and contamination.

Maintenance and Lifespan

In a 24/7 automated facility, maintenance windows are small. Choosing components that require less lubrication or are self-adjusting can save hundreds of man-hours per year.

Common Power Transmission Problems (and How to Fix Them)

Even the best systems encounter issues. Recognizing them early is key.

Vibration and Noise

Excessive noise usually indicates misalignment or wear. If a gearbox sounds like it’s grinding rocks, it’s time to check the lubrication or gear teeth.

Fix: Regularly check alignment using laser tools and ensure couplings are in good condition.

Component Wear and Failure

Belts stretch and chains elongate over time. If not tensioned correctly, they will slip.

Fix: Implement a preventive maintenance schedule to replace “wear parts” before they fail.

Energy Loss

Heat radiating from a gearbox or bearing means energy is being wasted fighting friction.

Fix: Upgrade to high-efficiency components and ensure proper lubrication levels.

The Future of Power Transmission in Industrial Automation

The hardware of the future is getting smarter. We are entering the era of “Industry 4.0,” where mechanical components talk to digital systems.

Smart Sensors

Modern gearboxes and bearings are now being equipped with sensors that monitor temperature and vibration in real-time. They can alert the maintenance team that a failure is imminent weeks before it happens.

Energy Efficiency

As energy costs rise, there is a push for ultra-efficient transmission designs that minimize friction and maximize output.

Predictive Maintenance

Instead of fixing things when they break, automation trends are moving toward predictive maintenance. Data analysis predicts exactly when a belt needs changing, preventing unexpected downtime entirely.

Why Power Transmission Determines Automation Success

We often get distracted by the flashiness of robotics and AI software. But automation performance starts with strong power transmission. You can write the best code in the world, but if the belt slips, the robot misses.

Investing in high-quality industrial power transmission components is an investment in reliability. It ensures that production targets are met, safety is maintained, and energy bills are kept in check. Reliable systems lead to higher productivity and, ultimately, a healthier bottom line.

If you are looking to optimize your facility, don’t overlook the mechanical muscle behind the machine. Explore high-quality power transmission components today and partner with experts who understand that the smallest gear can make the biggest difference.