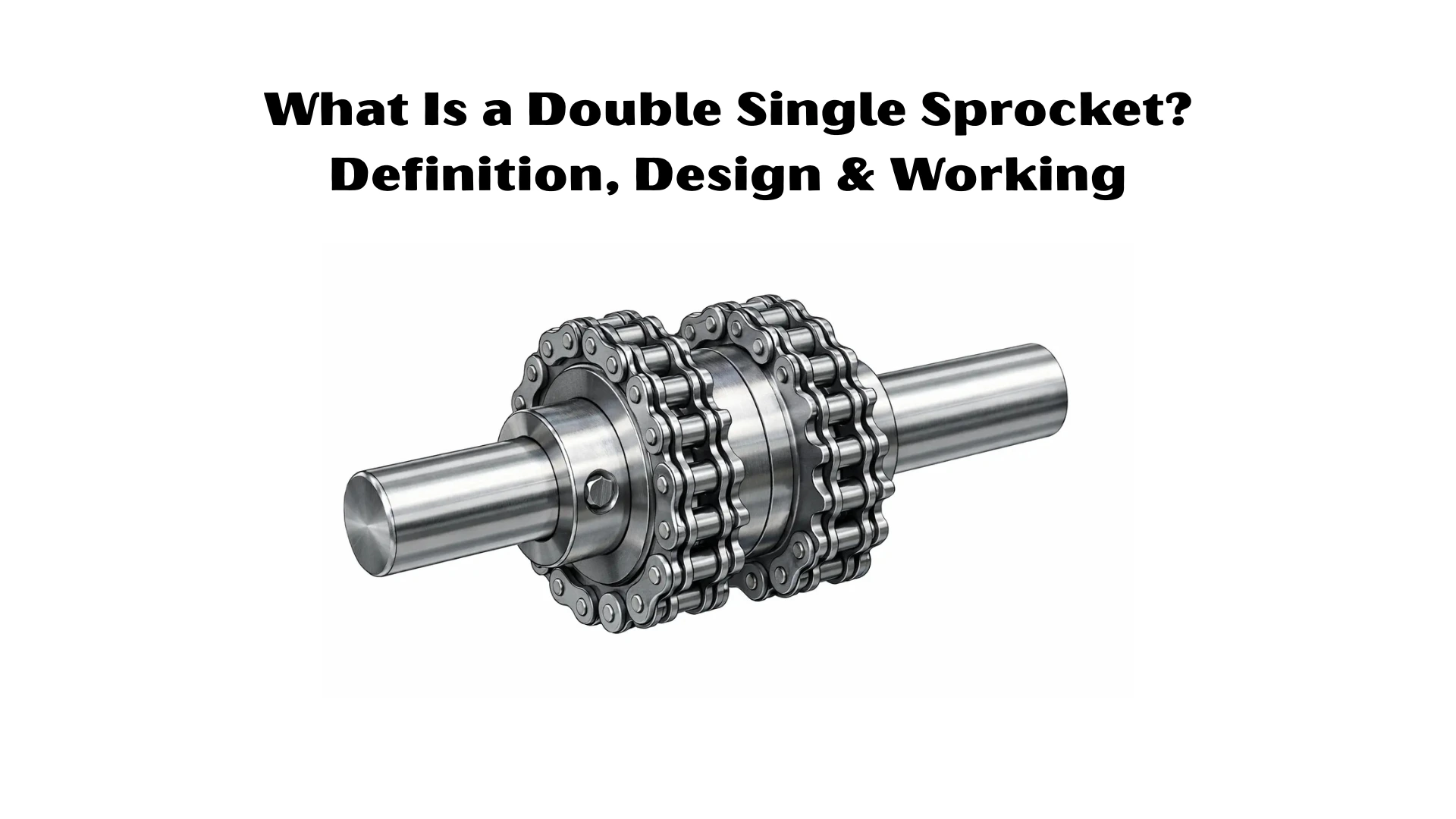

What Is a Double Single Sprocket? Definition, Design & Working

Power transmission systems are the backbone of modern industry. From massive agricultural harvesters to intricate packaging lines, the ability to transfer rotational motion efficiently determines the success of the operation. At the heart of these systems lies the sprocket—a simple yet critical component that engages with a chain to drive machinery.

While standard sprockets are ubiquitous, complex industrial applications often require specialized solutions to handle unique load distributions and drive configurations. Selecting the wrong component can lead to premature wear, system failure, and costly downtime.

Enter the double single sprocket. This specialized component is designed to solve specific challenges in power transmission that a standard single sprocket cannot address. Whether you are an engineer designing a new conveyor system or a maintenance manager looking to upgrade existing equipment, understanding the mechanics and benefits of the double single sprocket is essential for optimizing performance.

What Is a Double Single Sprocket?

A double single sprocket is a specialized type of sprocket designed to operate two single-strand roller chains from a single hub. Unlike multi-strand sprockets that engage a single chain with multiple rows of links, a double single sprocket effectively acts as two independent single sprockets fused.

The term “double single” can be confusing at first glance. It refers to the configuration: Double rows of teeth, designed to accommodate single-strand chains.

How it differs from a standard single sprocket

A standard single sprocket has one row of teeth and engages one chain. If you need to drive two parallel shafts or split power from a central drive shaft to two different locations, using two separate single sprockets can be cumbersome. It requires more shaft space and complicates alignment.

A double single-chain sprocket solves this by combining two tooth profiles onto a single central hub. This design allows a single drive shaft to power two separate chains simultaneously, often in opposite directions or to different driven sprockets, without the need for complex spacing or multiple hubs.

Typical use cases

You will most often find these components in applications where a central drive needs to power adjacent roller conveyors. For example, in a live roller conveyor system, a double single sprocket is mounted on a drive shaft. One set of teeth receives power from the motor via a chain, while the second set of teeth transmits that power to the next roller in the line.

Key Components of a Double Single Sprocket

To understand how this component functions, it helps to break down its anatomy. A high-quality sprocket is more than just a piece of metal with teeth; it is a precision-engineered part.

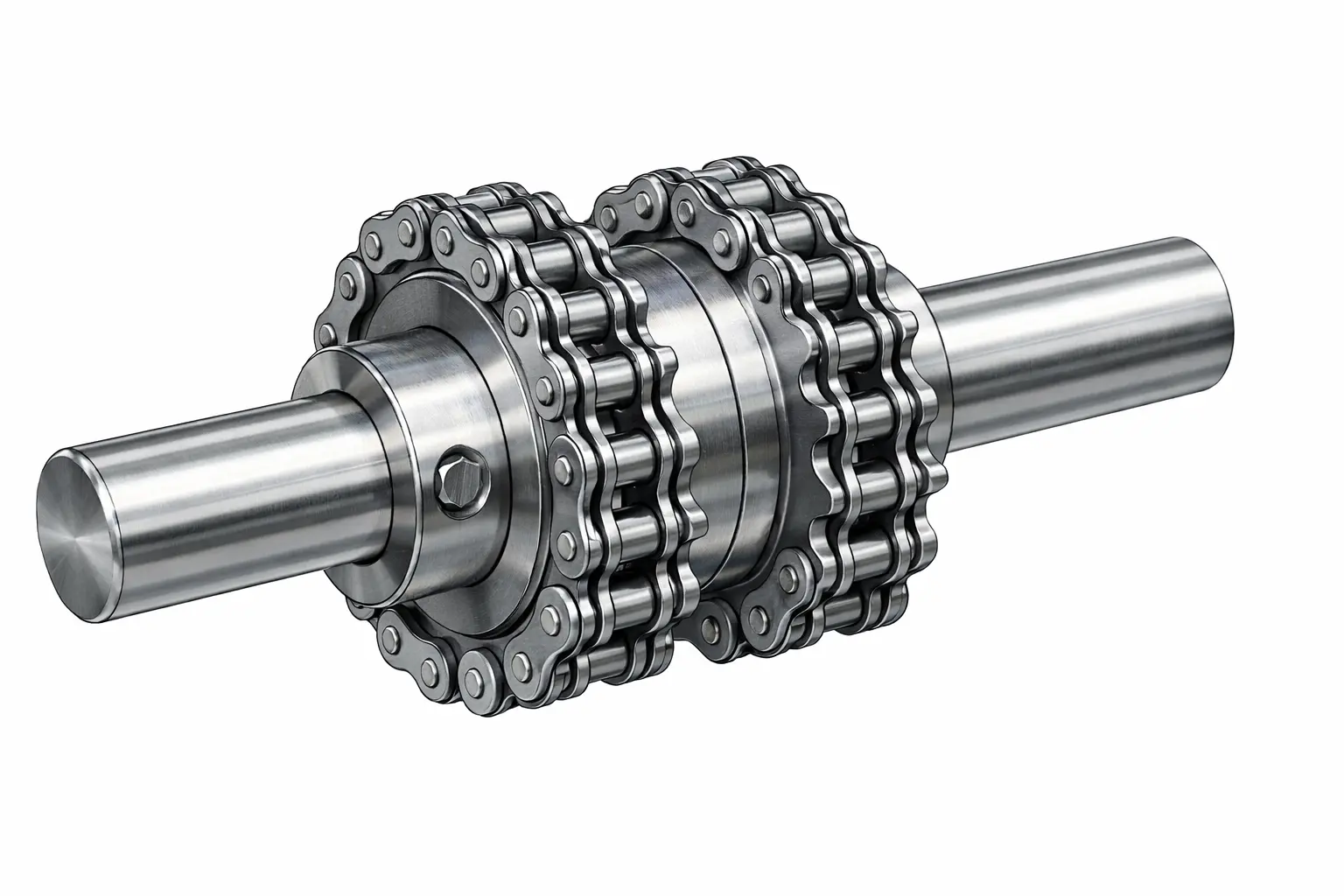

Hub

The hub is the central part of the sprocket that fits onto the shaft. In a double single configuration, the hub must be robust enough to handle the torque load of two chains simultaneously.

Teeth Profile

The teeth are precision-cut to match the pitch of the roller chain. The profile must be exact to ensure smooth engagement and disengagement of the chain rollers, minimizing friction and wear.

Bore and Keyway

The bore is the center hole that accepts the drive shaft. Most industrial sprockets include a keyway—a slot cut into the bore—and a set screw. This locks the sprocket to the shaft, preventing it from spinning freely and ensuring direct torque transmission.

Chain Seating Area

This is the space between the teeth where the chain rollers rest. Proper seating is crucial for distributing the load evenly across the sprocket.

Material Construction

Durability is paramount. These sprockets are typically manufactured from high-grade carbon steel (like 1045 steel) or stainless steel for corrosive environments. For heavy-duty applications, the teeth are often hardened to resist wear and tear.

Design of a Double Single Sprocket

The structural design of a double single sprocket is unique because it must accommodate two independent chains without them interfering with one another.

Structural design overview

The sprocket features a solid body with two parallel rows of teeth. The distance between these two rows is critical. Unlike a duplex sprocket, where the rows are spaced to fit a double-strand chain, the rows on a double single sprocket are spaced to allow two separate single-strand chains to operate independently.

Teeth arrangement and spacing

The spacing is engineered to ensure that the side plates of the two chains do not rub against each other, which would cause friction and potential failure. Manufacturers adhere to specific standards to ensure this clearance is maintained regardless of the chain size.

Load distribution concept

The design allows for split-load distribution. Power enters the sprocket through the shaft (or one chain loop) and is distributed out through the chains. Because the sprocket is a single solid unit, there is no slippage between the two rows of teeth, ensuring perfect synchronization between the two chains.

ANSI / ISO design references

Most reliable sprockets are manufactured according to ANSI (American National Standards Institute) or ISO specifications. For example, a 40 double single sprocket is designed to ANSI B29.1 standards to fit a #40 roller chain. Adhering to these standards ensures interchangeability and predictable performance.

How a Double Single Sprocket Works

The working principle of a double single sprocket relies on the mechanical advantage of rotary motion converted into linear motion via chains.

Step-by-step working principle

- Input Power: The drive shaft rotates, turning the sprocket hub.

- Engagement: As the sprocket turns, the teeth on both rows engage with the rollers of their respective chains.

- Transmission: The torque from the shaft is transferred to the chains.

- Motion: The chains move linearly, pulling whatever load or driven sprocket is attached to them.

Chain and sprocket interaction

The interaction is continuous. As one tooth disengages from a chain link, the next tooth engages a new link. Because there are two rows, this happens simultaneously on both sides of the sprocket.

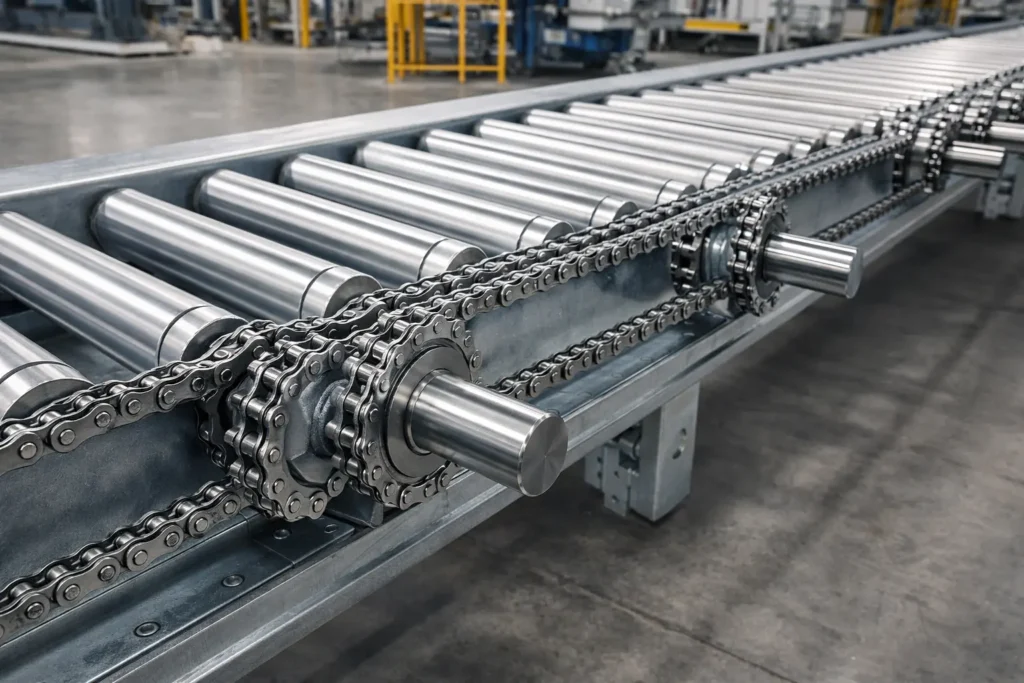

Motion synchronization between shafts

One of the primary functions of this sprocket type is synchronization. Because both rows of teeth are machined onto the same piece of material, they rotate at the same speed. If you are using this sprocket to drive two parallel conveyor rollers, those rollers will move at identical speeds. This is critical in material handling, where uneven speeds can cause packages to rotate or jam.

Applications of Double Single Sprockets

Due to their unique ability to split power and synchronize motion, these sprockets are found in a wide variety of industrial sectors.

Conveyor Systems

This is the most common application. In “chain-driven live roller” (CDLR) conveyors, double single sprockets are welded or keyed to the rollers. A continuous loop of chain connects one roller to the next in a daisy-chain fashion. The double single sprocket allows one chain to come in from the previous roller and a second chain to go out to the next roller.

Agricultural Machinery

In farming equipment, space is often at a premium, but power needs to be distributed to multiple mechanisms (like cutters and feeders) simultaneously. A double single-chain sprocket allows engineers to drive multiple subsystems from a single main shaft.

Industrial Automation Equipment

Robotic assembly cells and automated manufacturing lines use these sprockets to ensure different parts of a machine move in perfect unison.

Packaging and Material Handling

From boxing machines to palletizers, keeping products moving smoothly requires precise timing. The synchronized nature of double single sprockets makes them ideal for these sensitive operations.

Advantages of Using a Double Single Sprocket

Why choose this specific design over simply putting two single sprockets on a shaft?

Improved Load Handling Capacity

While the sprocket itself doesn’t necessarily generate more power, its solid construction provides a rigid, stable platform for driving two chains. This minimizes the “wobble” that can sometimes occur when stacking loose sprockets.

Better Chain Alignment

Alignment is the enemy of chain life. When you mount two separate single sprockets, you have to manually space and align them on the shaft. A double single sprocket comes pre-spaced with precision. You only need to align the hub once, and both chains are automatically aligned relative to each other.

Reduced Wear and Maintenance

Because alignment is inherent to the design, the chains run straighter. This reduces side-loading on the sprocket teeth and wear on the chain side plates, leading to longer maintenance intervals.

Higher Operational Efficiency

Fewer moving parts and better alignment translate to less energy lost to friction. The system runs smoother and cooler.

Double Single Sprocket vs Other Sprocket Types

Choosing the right component can be confusing given the similar naming conventions. Here is how the double single compares to its cousins.

Double Single vs. Single Sprockets

As mentioned, replacing two single sprockets with one double single unit saves shaft space and ensures perfect relative alignment between the two chain runs. It simplifies installation significantly.

Double Single vs. Duplex Sprockets

This is the most common confusion.

- Duplex Sprocket: Designed for a double-strand chain (two chains connected by common pins). The teeth are closer together.

- Double Single Sprocket: Designed for two separate single-strand chains. The gap between the tooth rows is wider to accommodate the side plates of two independent chains.

Do not try to run two single chains on a duplex sprocket; they will rub and fail.

Double Single vs. Double Pitch Sprockets

A double pitch sprocket is designed for a double pitch chain (where the link length is twice the standard). It has a completely different tooth profile. It is not related to the number of chain rows.

Common Sizes and Specifications

These sprockets are categorized primarily by the chain pitch they are designed to accept.

Available Pitch Sizes

The most common industrial sizes align with ANSI standard chain numbers:

- 35 Double Single: For light-duty applications.

- 40 Double Single Sprocket: Very common in light-to-medium conveyors.

- 50 and 60 Double Single: Used in heavier industrial machinery.

- 80 and up: For heavy-duty power transmission.

Tooth Count Range

You can find these sprockets in a wide range of tooth counts, typically from as few as 12 teeth up to 30 or more, depending on the desired speed ratio and torque requirements.

Bore and Hub Options

- Stock Bore: Comes with a small hole that must be re-machined to fit your shaft.

- Finished Bore: Machined to a specific shaft size with a keyway and set screws included.

- Taper-Lock / QD Bushings: Allows for a flexible fit on various shaft sizes by changing a bushing.

Customization Possibilities

While standard sizes cover 90% of applications, custom sprockets can be manufactured with specific materials (like plastic for food safety or bronze for spark resistance), specialized coatings, or non-standard tooth counts.

Installation and Maintenance Tips

Even the best double single chain sprocket will fail if installed incorrectly.

Proper Installation Guidelines

- Shaft Inspection: Ensure the shaft is clean, straight, and free of burrs.

- Mounting: Slide the sprocket onto the shaft. Do not hammer it directly, as this can damage the hub or bearings.

- Alignment: Use a straightedge or laser alignment tool to ensure the sprocket is perfectly in line with the driven or driver components.

- Securing: Tighten set screws or bushings to the manufacturer’s recommended torque settings.

Lubrication Requirements

Chains require lubrication to function. The sprocket teeth also benefit from a film of oil to reduce metal-on-metal contact. Ensure your maintenance schedule includes regular lubrication suitable for the operating environment.

Inspection and Replacement

Check the sprocket teeth regularly. If the teeth start to look hooked or pointed (like a shark’s fin), the sprocket is worn and needs replacement. Replacing a chain without replacing a worn sprocket will destroy the new chain rapidly.

Common Problems and Troubleshooting

Chain Slipping

If the chain jumps over the teeth, check for:

- Excessive chain slack (tension needs adjustment).

- Severely worn sprocket teeth.

- The wrong chain size for the sprocket pitch.

Excessive Wear

Rapid wear usually indicates misalignment. Check that the shafts are parallel and the sprockets are in the same plane. It could also indicate a lack of lubrication or abrasive debris in the system.

Noise and Vibration

A noisy drive is a sign of trouble. It often points to a “tight spot” in the chain, misalignment, or a loose set screw allowing the sprocket to wobble on the shaft.

Frequently Asked Questions (FAQs)

What chain is compatible with a double single sprocket?

These sprockets are compatible with ANSI standard single-strand roller chains. For example, a #40 double single sprocket requires two separate loops of #40 roller chain.

Can it handle heavy loads?

Yes, provided it is sized correctly. The load capacity is determined by the material of the sprocket, the size of the chain, and the diameter of the shaft. Hardened teeth are recommended for high-load applications.

Are custom sprockets available?

Absolutely. If your application requires a specific bore size, a non-standard tooth count, or materials like stainless steel for food processing, custom manufacturing is a viable option.

How long does a double single sprocket last?

Lifespan varies based on load, lubrication, and environment. However, in a well-maintained, clean environment with proper lubrication, a quality steel sprocket can last for thousands of operational hours.

Why Choose Us for Double Single Sprockets?

When your production line depends on reliable motion control, the quality of your components matters. We specialize in providing top-tier power transmission solutions that keep your industry moving.

Precision Manufacturing and Quality Control

Our sprockets are manufactured to tight tolerances, ensuring perfect concentricity and tooth profile accuracy. This translates to smoother operation and less vibration in your equipment.

Use of Premium-Grade Materials

We do not cut corners on steel quality. Whether you need standard carbon steel or corrosion-resistant alloys, our products are built to withstand the rigors of industrial use.

Expert Technical Support

Not sure if you need a 40 double single sprocket or a duplex setup? Our team of engineers is available to guide you through the selection process, ensuring you get the exact part needed for your specific application.

Conclusion

The double single sprocket is a versatile problem-solver in the world of power transmission. By allowing two independent chains to be driven from a single hub, it enables complex conveyor layouts and synchronized machinery designs that would be difficult to achieve with standard components.

From understanding the critical difference between double single and duplex sprockets to recognizing the importance of proper alignment, making an informed choice ensures efficiency and longevity for your equipment.

Don’t let a simple component be the weak link in your operation. If you are looking to upgrade your conveyor system or need a replacement for a worn-out drive, explore our catalog of high-performance sprockets today.