Chain Parts Guide: Roller Chain Components Explained

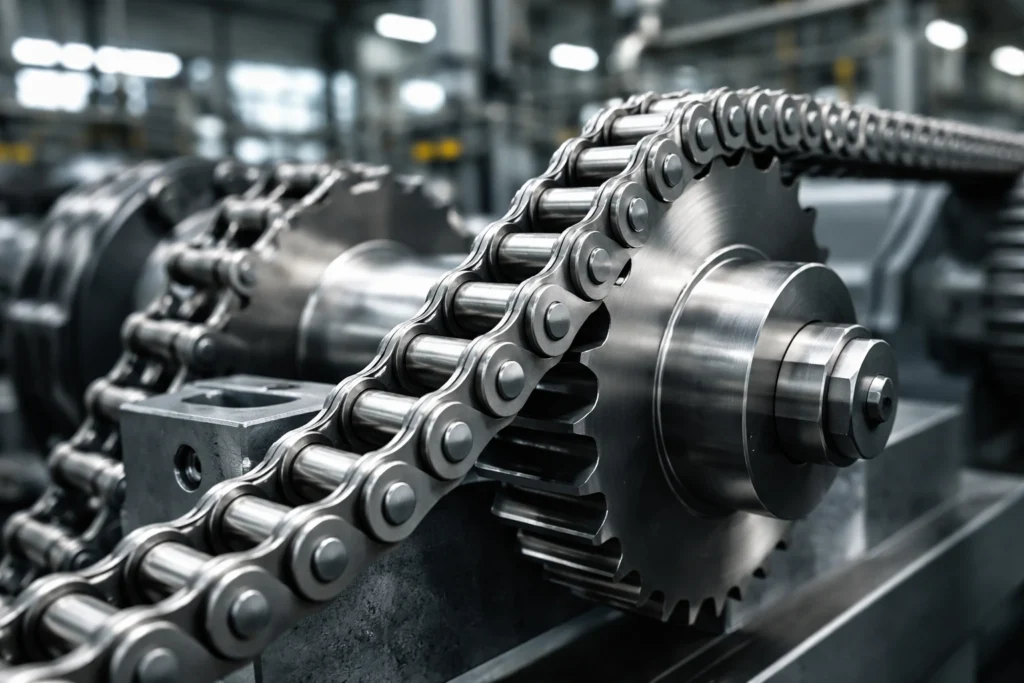

Whether you’re managing a high-speed manufacturing line, maintaining agricultural machinery, or overseeing an automotive assembly plant, the reliability of your system often hangs by a thread—or rather, a chain. Understanding chain parts is fundamental to ensuring the smooth operation of mechanical systems.

Roller chains are ubiquitous in the industrial world, yet they are frequently overlooked until a failure occurs. A broken link or a seized pin can lead to costly downtime, safety hazards, and expensive repairs. By gaining a deeper understanding of roller chain components, you empower yourself to make better purchasing decisions, implement more effective maintenance schedules, and ultimately optimize the performance of your machinery.

This guide explores the anatomy of parts of chains, from the smallest pin to the master link, explaining how these individual pieces work in harmony to transmit power efficiently across industries ranging from food processing to heavy construction.

What Are Roller Chains?

At its most basic level, a roller chain is a mechanical device used to transmit power between two rotating shafts. It functions by engaging with the teeth of a sprocket, transferring rotational motion into linear motion and back again.

Unlike belt drives which rely on friction and can slip, or cable systems which have limited load capacities, roller chains provide a positive, non-slip drive with high efficiency. The genius of the roller chain lies in how its individual chain pieces articulate. They are designed to flex around sprockets while maintaining high tensile strength to pull heavy loads.

While there are many types of chains—such as leaf chains for lifting or silent chains for high-speed timing—the standard roller chain remains the most versatile and widely used option in power transmission.

Overview of Chain Parts

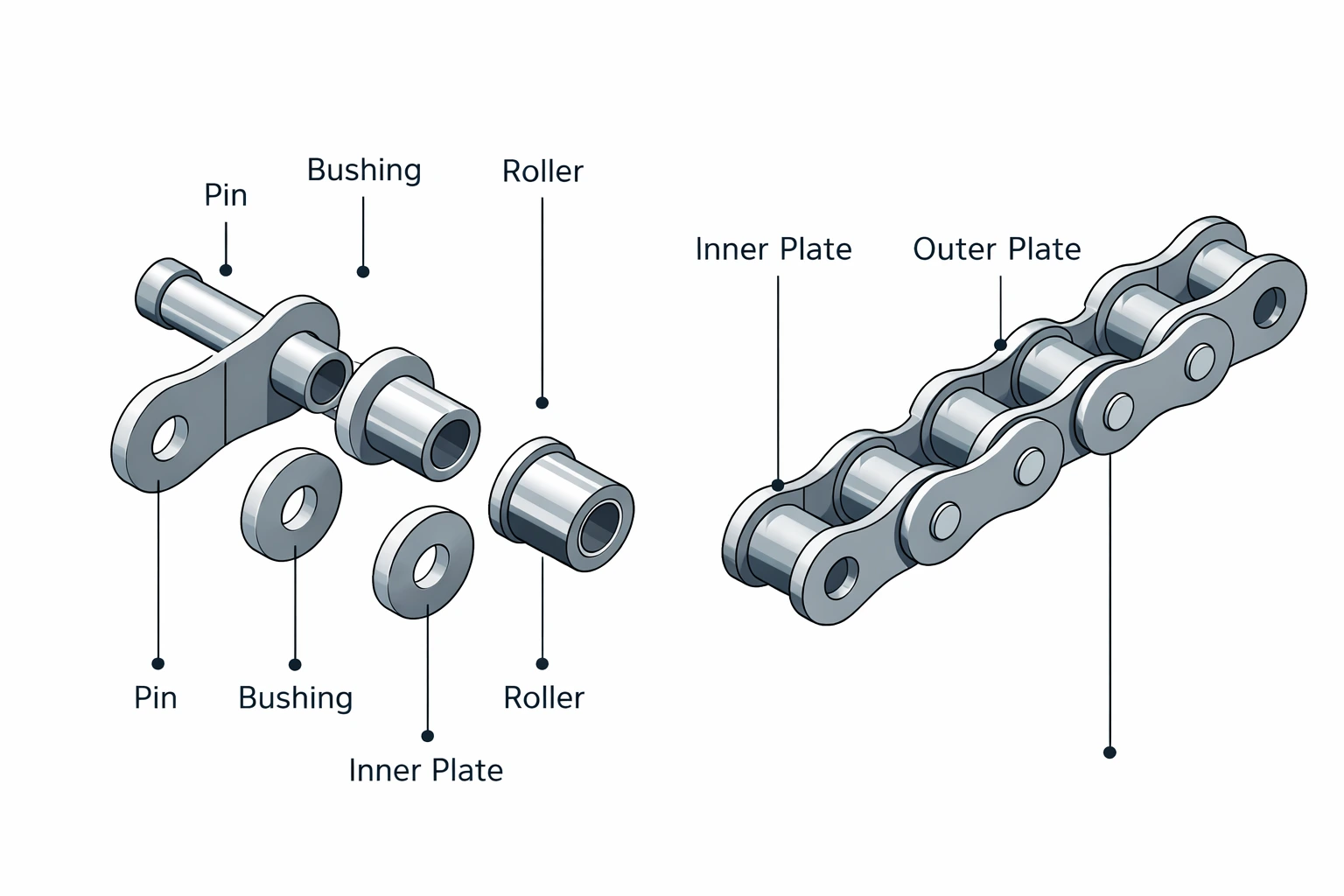

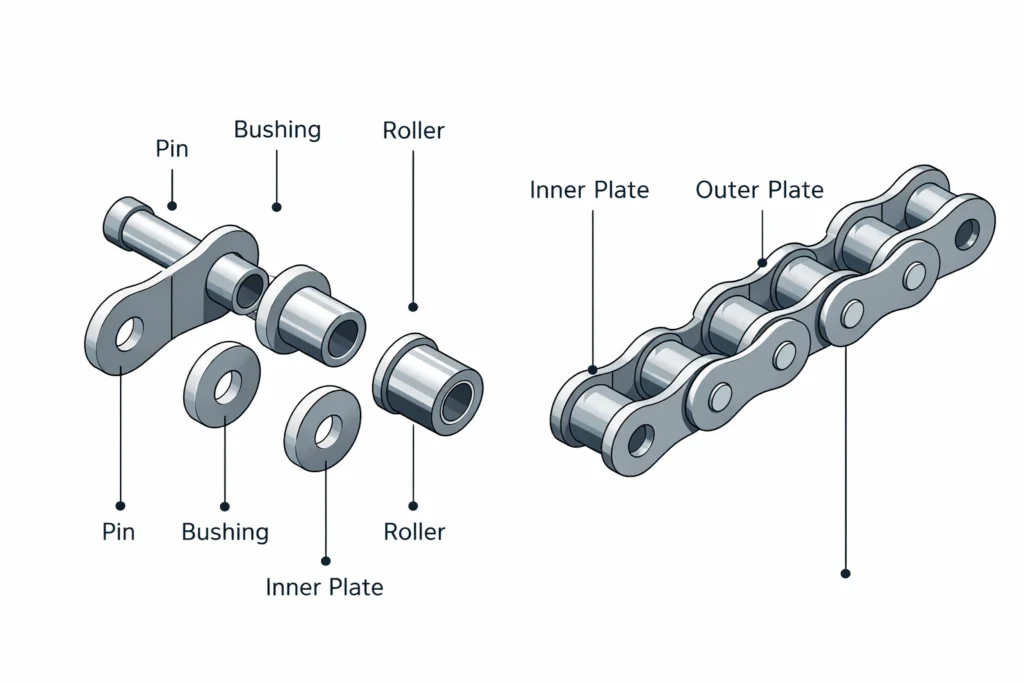

A roller chain might look like a single continuous unit, but it is actually a complex assembly of alternating links. It is constructed from multiple precision roller chain components that must fit together perfectly to function.

Every single component plays a critical role. If one part is manufactured with poor tolerances or substandard materials, the integrity of the entire chain is compromised. These chain parts function as a complete system to bear loads, resist wear, and reduce friction during operation.

Broadly speaking, a roller chain consists of two types of links arranged in an alternating pattern: pin links (inner links) and roller links (outer links). Let’s break down the specific anatomy.

Core Roller Chain Components

To truly understand how a chain works, we must look at the five core chain parts that make up the assembly.

4.1 Inner Plates

The inner plates form the body of the inner link. These plates work in pairs and serve as the anchor for the bushings. Their primary function is to maintain the precise spacing of the rollers and bushings while enduring the repeated stress of tension. The structural integrity of inner plates is vital, as they must resist elongation and fatigue failure.

4.2 Outer Plates

Similar to inner plates, the outer plates form the body of the pin link. They are pressed onto the pins and hold the chain together laterally. The outer plates bear the brunt of the tensile load (the pulling force) exerted on the chain. Thicker or heat-treated outer plates are often used in heavy-duty chains to increase shock resistance and ultimate tensile strength.

4.3 Pins

Pins are the pivot points of the chain. They pass through the bushings and are riveted or cottered into the outer plates. The pin is perhaps the most critical of all roller chain parts regarding wear life. It bears the shearing load and rotates inside the bushing every time the chain flexes around a sprocket. If a pin is too soft, it will wear down quickly, causing the chain to “stretch” (elongate). If it’s too brittle, it may snap under shock loading.

4.4 Bushings

Bushings are hollow cylinders that are press-fitted into the inner plates. They act as a bearing surface for the pin and a support surface for the roller. The bushing protects the pin from direct contact with the roller and absorbs much of the shock during engagement with sprocket teeth. High-quality parts of chains feature solid bushings (cold-forged from a single piece of steel) rather than curled bushings, as solid versions offer significantly better fatigue life and wear resistance.

4.5 Rollers

The roller is the component that gives the “roller chain” its name. It spins freely over the bushing. When the chain engages a sprocket, the roller contacts the tooth and rotates, converting sliding friction into rolling friction. This significantly reduces wear on both the sprocket teeth and the chain itself. Without free-spinning rollers, the friction would be immense, leading to rapid heat buildup and failure.

Additional Chain Parts and Accessories

Beyond the standard links, several specialized chain pieces and accessories are necessary for installation and specific applications.

5.1 Master Links (Connecting Links)

A standard roller chain is endless, but to install it, you usually need a way to connect the two ends. This is where the Master Link (or Connecting Link) comes in. It typically features a removable plate secured by a spring clip or cotter pin. While convenient for installation and maintenance, the master link is often the weakest point in the chain assembly, typically rated at about 80% of the strength of a riveted link.

5.2 Offset Links

Sometimes, the length of a chain requires an odd number of links. Since standard links must be added in pairs (one inner, one outer), an Offset Link (or “half link”) is used to close the loop. These combined links feature both a pin and a roller end. Like master links, offset links reduce the overall working load limit of the chain and should only be used when absolutely necessary.

5.3 Attachment Links

In conveyor applications, roller chain components often include attachments. These are modified inner or outer plates featuring bent tabs, extended pins, or rubber profiles. They allow the chain to do more than just transmit power; they allow it to transport goods, mount buckets, or push products along an assembly line.

5.4 Sprockets

While not technically part of the chain itself, sprockets are the essential partner to roller chain parts. A sprocket is a profiled wheel with teeth that mesh with the chain. The selection of the sprocket—its number of teeth, material, and hardness—is just as important as the chain selection. Using a new chain on worn sprockets can ruin the new chain in a fraction of its expected lifespan.

5.5 Chain Tensioners and Guides

Chains elongate over time as the pins and bushings wear. Chain tensioners take up this slack to prevent the chain from jumping teeth or vibrating excessively. Guides help keep the chain on track, reducing side-to-side movement and protecting the chain parts from misalignment wear.

How Roller Chain Components Work Together

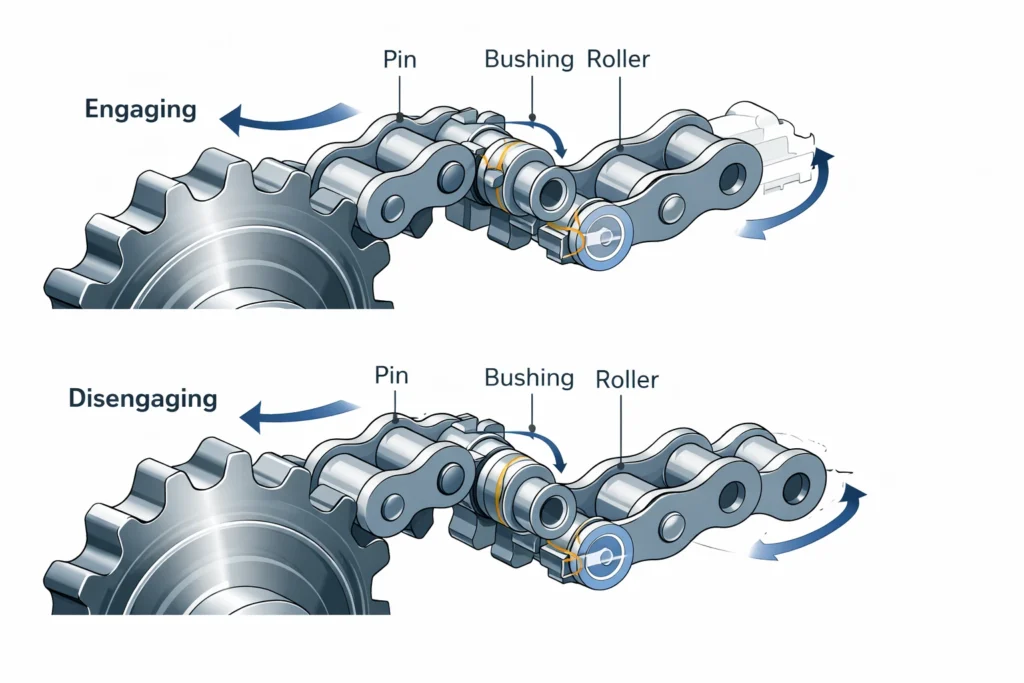

The magic of a roller chain happens when all these chain pieces articulate under load.

- Engagement: As the chain approaches the driving sprocket, the roller contacts the tooth root.

- Articulation: The chain bends. The pin rotates inside the bushing, while the roller spins on the outside of the bushing.

- Load Transfer: The outer plates pull the pins, which pull the bushings, which pull the inner plates. This transfers the mechanical energy from the driving shaft to the driven shaft.

- Disengagement: As the chain leaves the sprocket, it straightens out, ready to cycle back around.

If even one component is out of spec—for instance, if a pin is slightly bent—it causes friction spikes and creates a “kink” in the system. This underscores why precision manufacturing of parts of chains is non-negotiable.

Common Materials Used in Chain Parts

The environment in which the chain operates dictates the material required for the roller chain components.

- Carbon Steel: The standard for general industrial applications. These parts are often heat-treated (case-hardened) to provide a hard, wear-resistant surface while maintaining a tough, ductile core to absorb shock.

- Stainless Steel: Essential for food processing, medical, or marine environments. Stainless steel chain parts resist corrosion and rust but generally have a lower tensile strength and wear life compared to carbon steel.

- Nickel-Plated: A middle ground. These chains offer better corrosion resistance than carbon steel (thanks to the coating) but retain higher strength than stainless steel.

- Plastic/Acetal: Used in light-duty applications where noise reduction, cleanliness, or chemical resistance is paramount.

How to Choose the Right Roller Chain Parts

Selecting the correct chain parts prevents premature failure. Consider the following:

- Size and Pitch: The pitch is the distance between the centers of two adjacent pins. Common ANSI sizes include #40, #60, and #80. This must match your sprockets exactly.

- Load Capacity: Calculate the horsepower and torque requirements. Ensure the chain’s working load limit exceeds your maximum operating load.

- Environment: Is it hot? Dusty? Wet? Standard roller chain parts may seize in high heat or rust in moisture. Specialized coatings or sealed O-ring chains may be required.

- Compatibility: Never mix chain pieces from different manufacturers if possible. While dimensions are standardized, tolerances and metallurgical recipes vary, leading to uneven wear.

Common Problems in Chain Parts and Their Causes

Recognizing the symptoms of failing parts of chains can save you from catastrophic equipment failure.

- Elongation (Stretch): This is rarely caused by the metal physically stretching. Instead, it is the result of material removal from the pins and bushings due to friction.

- Rust and Corrosion: Caused by moisture or chemical exposure, leading to pitted surfaces and seized links.

- Misalignment: If the sprockets aren’t aligned, the inner plates will rub against the sprocket teeth, causing side wear on the plates.

- Broken Plates: Usually a sign of shock loading (sudden impact) that exceeded the chain’s tensile strength, or hydrogen embrittlement.

Maintenance Tips for Longer Chain Life

To get the most out of your roller chain components, adhere to a strict maintenance schedule.

- Lubrication: This is the single most important factor. Oil creates a film between the pin and bushing, preventing metal-on-metal contact. Use the correct viscosity oil for your operating temperature.

- Inspection: Check regularly for stiff links, protruding pins, or cracked plates. Measure elongation; if the chain has elongated more than 3% (or 1.5% for fixed center drives), it’s time to replace it.

- Cleaning: Periodically clean debris from the chain. A buildup of grit acts like grinding paste, rapidly wearing down chain parts.

- Sprocket Replacement: A general rule of thumb is to replace sprockets every time you replace the chain. Putting a new chain on old sprockets will cause the chain to wear out prematurely.

Buying Guide: Choosing the Right Supplier

Not all chain parts are created equal. When sourcing components, look for:

- Quality Standards: Ensure the supplier meets ANSI (American National Standards Institute) or ISO (International Organization for Standardization) requirements.

- Availability: Do they stock the roller chain components you need, or will you be waiting weeks for a replacement pin?

- Technical Support: Can they help you calculate drive requirements or troubleshoot failure modes?

Frequently Asked Questions (FAQ)

What are the main parts of chains?

The five main components are pins, bushings, rollers, inner plates, and outer plates. Together, these form the pin links and roller links that make up the chain.

How often should roller chain parts be replaced?

Replacement depends on usage, load, and maintenance. However, a chain should generally be replaced when it has elongated by 1.5% to 3% of its original length.

Can individual chain pieces be replaced?

While you can replace a broken link with a master link or offset link, it is often a temporary fix. If one part has failed due to wear or fatigue, the rest of the chain is likely close to failure as well. Replacing the entire strand is usually safer and more cost-effective.

Which material is best for roller chain components?

Carbon steel is best for strength and general use. Stainless steel is best for corrosion resistance (food/marine). Nickel-plated is a hybrid for mild corrosion resistance and high strength.

How do I select the correct roller chain parts?

Measure the pitch (distance between pin centers), roller diameter, and inside width. Match these to ANSI or ISO standards (e.g., ANSI #50) and ensure the material rating matches your environmental needs.

Optimize Your Operations with Premium Chain Parts

Understanding the intricacies of chain parts is more than an academic exercise—it is a business necessity. The correct selection, installation, and maintenance of roller chain components lead directly to improved efficiency, longer equipment lifespans, and a safer working environment.

At our company, we understand that a chain is only as strong as its weakest link. That’s why we supply high-quality roller chains and individual chain pieces engineered for durability and performance. Whether you are operating in heavy agriculture, automotive assembly, or precision manufacturing, our components are tested to withstand the toughest conditions.

Don’t let a small component cause a big problem.

Ready to upgrade your system’s reliability?

Request a quote today to explore our full range of roller chains and accessories. We’d like to help you keep your business moving.