Roller Chain Coupling in Toledo, OH

Toledo’s industrial heartbeat relies on machinery that runs smoothly, efficiently, and without unexpected interruptions. From automotive assembly lines to glass manufacturing, the equipment powering the Glass City needs robust components to handle high torque and heavy loads. This is where high-quality double roller chain coupling solutions come into play.

We provide durable, industrial-grade power transmission components designed to keep your operations moving. Whether you are in Maumee, Perrysburg, or right here in Toledo, Ohio, having a local supplier for roller chain couplings ensures you get the parts you need before a minor maintenance issue turns into major downtime. Our inventory includes a wide range of roller chain and sprocket coupling options tailored to meet the rigorous demands of Midwest manufacturing.

What Is a Double Roller Chain Coupling?

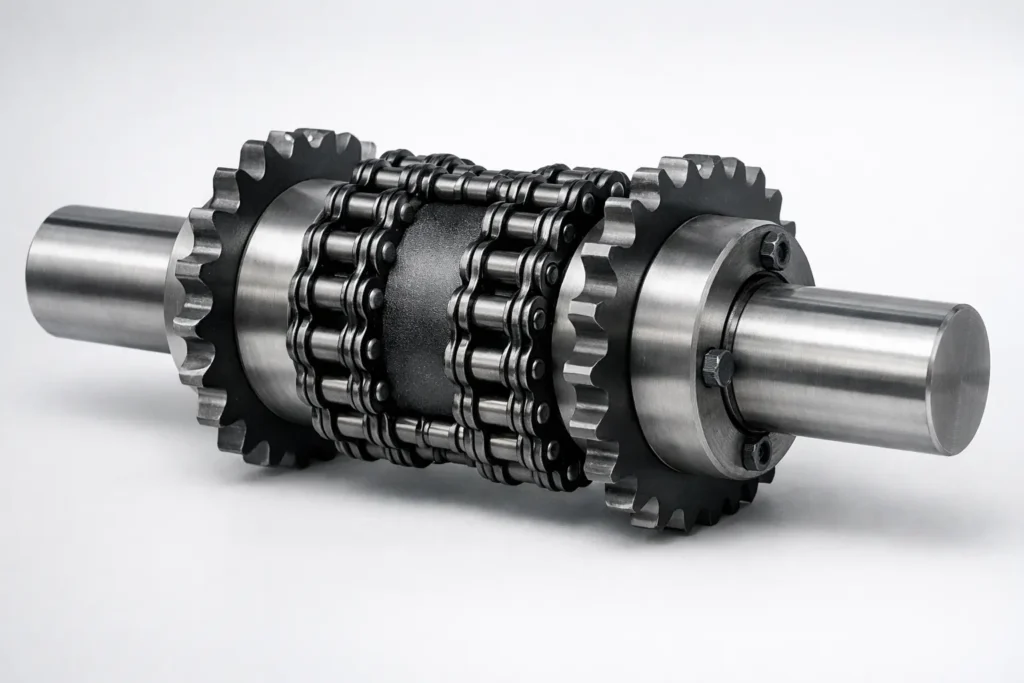

A double roller chain coupling is a flexible coupling used to connect two shafts, transmitting power from one to the other. It consists of two sprockets—one attached to each shaft—connected by a double-strand roller chain wrapped around them. This simple yet effective design creates a strong, flexible connection capable of transmitting significant torque.

Unlike rigid couplings, a double roller chain design offers flexibility. It accommodates slight misalignment between connected shafts, which protects bearings and other machinery components from excessive stress. The chain can be easily removed by detaching a master link, making maintenance and replacement far simpler than with many other coupling types. This combination of durability, misalignment tolerance, and cost-effectiveness makes it a staple in heavy industrial applications.

Roller Chain and Sprocket Coupling for Industrial Machinery

Understanding the mechanics of a roller chain and sprocket coupling reveals why it is so popular in heavy-duty sectors. The system relies on the interaction between the hardened teeth of the sprockets and the precision-engineered rollers of the chain. This engagement ensures a positive grip, preventing slippage even under heavy loads.

The advantages go beyond simple power transmission. These couplings are rugged and can withstand harsh environments, including those with dust, dirt, or moisture. They are compact relative to the torque they can handle, allowing for efficient use of space within complex machinery layouts. For industries requiring high-torque transmission at lower speeds, this coupling style is often the most reliable choice.

Our Range of Roller Chain Couplings

We stock a diverse selection of couplings to suit various industrial needs. Finding the right fit is crucial for maximizing the lifespan of your equipment.

Double Roller Chain Coupling

Our flagship offering, the double roller chain coupling, provides superior strength and durability. It is designed for applications where high torque transmission is non-negotiable. The double-strand chain distributes the load more evenly, reducing wear on individual components.

Standard Roller Chain Couplings

For general-purpose applications, our standard couplings offer a balance of performance and economy. They are ideal for connecting motors to gearboxes, pumps, or conveyors where extreme loads may not be present, but reliability is still essential.

Customized Roller Chain & Sprocket Coupling Solutions

Every facility is different. If your machinery requires non-standard bore sizes, specific keyway configurations, or unique material treatments for corrosion resistance, we can provide customized solutions. We work to ensure your roller chain and sprocket coupling fits perfectly into your existing system.

Applications of Double Roller Chain Couplings in Toledo, OH

Toledo is home to a diverse industrial landscape, and our products support the machinery that powers our local economy. From the heavy manufacturing sectors in the city center to the logistics hubs in the suburbs, reliable couplings are essential.

Manufacturing Plants

General manufacturing facilities use these couplings on everything from mixers to packaging machinery. The ability to quickly disconnect the chain for maintenance is a favorite feature for plant managers looking to minimize downtime.

Automotive & Assembly Lines

With Toledo’s deep roots in the automotive industry, assembly lines require components that can run continuously. Double roller chain couplings handle the start-stop cycles and variable loads common in automotive production equipment.

Conveyor Systems

Material handling is critical for logistics and distribution. Conveyor drives frequently utilize roller chain couplings due to their durability and ability to handle the high torque needed to move heavy pallets and goods.

Steel, Glass & Heavy Industries

In the grueling environments of steel processing or glass manufacturing—industries synonymous with Toledo and nearby Maumee and Rossford—equipment is subjected to heat and debris. Our rugged couplings are built to withstand these punishing conditions without failing.

Technical Specifications of Our Double Roller Chain Couplings

We ensure all our products meet strict quality standards. When selecting a coupling, consider the following specifications:

- Torque Capacity: Engineered to handle high torque loads suitable for heavy machinery.

- Shaft Sizes: Available in a wide range of bore sizes to fit standard motor and gearbox shafts.

- Materials: Sprockets are typically made from hardened steel for longevity, with chains available in carbon steel or nickel-plated options for corrosion resistance.

- Operating Conditions: Capable of operating in diverse temperature ranges and environments.

- Maintenance: Simple lubrication and periodic inspection of the chain and sprocket teeth are all that is typically required.

Why Choose Our Roller Chain Couplings in Toledo, Ohio

Local presence matters. When a line goes down, waiting days for a shipment from the coast isn’t an option.

- Local Supply & Fast Delivery: We are based near you. This means faster shipping times or even same-day pickup options for urgent needs.

- Industrial-Grade Quality: We don’t cut corners. Our couplings are sourced from reputable manufacturers known for precision and durability.

- Competitive Pricing: We offer fair pricing on premium products, helping you keep your maintenance budget in check.

- Technical Support: Not sure which part you need? Our team understands roller chain and sprocket coupling technicalities and can guide you to the right choice.

- Experience: We know the Toledo market. We understand the specific needs of the glass, auto, and agricultural industries that drive our region.

Serving Toledo and Surrounding Ohio Areas

We are proud to serve the entire Northwest Ohio region. Our delivery and support network extends to:

- Toledo

- Perrysburg

- Maumee

- Sylvania

- Bowling Green

Wherever your facility is located in the greater Toledo area, reliable roller chain couplings are just a phone call away.

Frequently Asked Questions About Roller Chain Couplings

What is a double roller chain coupling used for?

It is used to connect two shafts—such as a motor shaft and a pump shaft—to transmit power while accommodating slight misalignment. The double chain design allows for high torque capacity and easy maintenance.

Do you supply roller chain couplings in Toledo, OH?

Yes, we supply a full range of couplings to Toledo and the surrounding communities, including Maumee, Sylvania, and Perrysburg.

What industries use roller chain and sprocket coupling?

They are widely used in automotive manufacturing, steel production, agricultural processing, packaging, and material handling (conveyors).

Can you customize roller chain couplings?

Absolutely. We can assist with custom bore sizes, keyways, and special materials to match your specific machinery requirements.

Get Double Roller Chain Couplings in Toledo Today

Don’t let worn-out parts slow down your production. Whether you need a replacement double roller chain coupling or are designing a new drive system, we have the expertise and inventory to help.