Chain Coupling in Toledo, Ohio

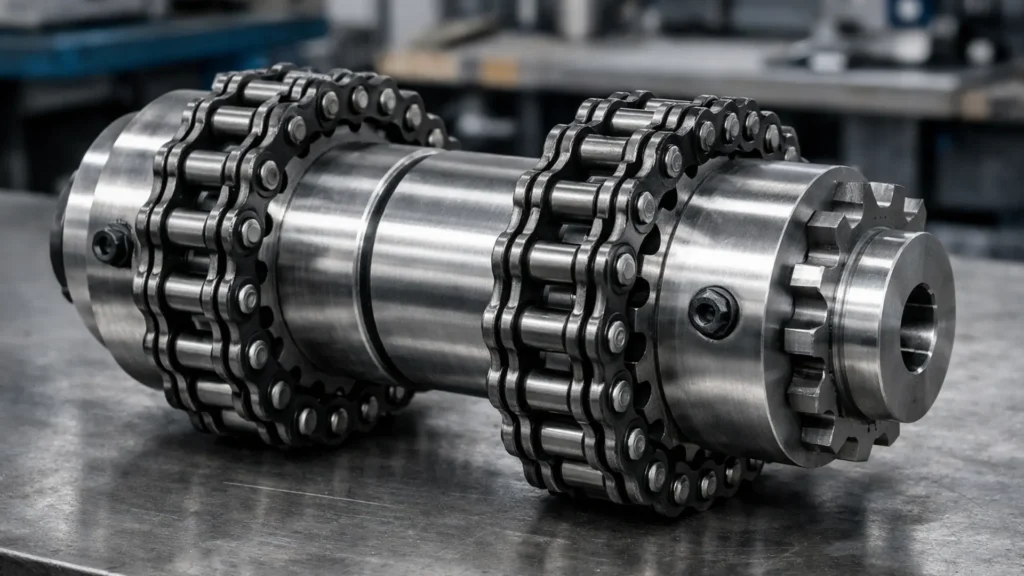

In the world of industrial power transmission, reliability is the currency that matters most. When equipment goes down, production stops, and costs rise. That is why selecting the right coupling for your machinery is critical. Chain couplings offer a robust solution, known for their exceptional strength, ease of maintenance, and ability to handle high torque in demanding environments.

At Ohio Roller Chain, we understand the stakes. With years of experience serving industries ranging from agriculture to mining, we provide high-quality couplings designed to keep your operations running smoothly. Whether you need a standard replacement or a custom solution, we have the expertise to deliver exactly what you need.

Ready to upgrade your power transmission system? [Request a Quote] today or [Download our Technical Datasheet] for detailed specifications.

What Is a Chain Coupling?

A chain coupling is a mechanical device used to connect two shafts end-to-end to transmit power. Unlike rigid couplings, which require perfect alignment, chain couplings are flexible. They are designed to transmit torque while accommodating slight misalignments between the driving and driven shafts.

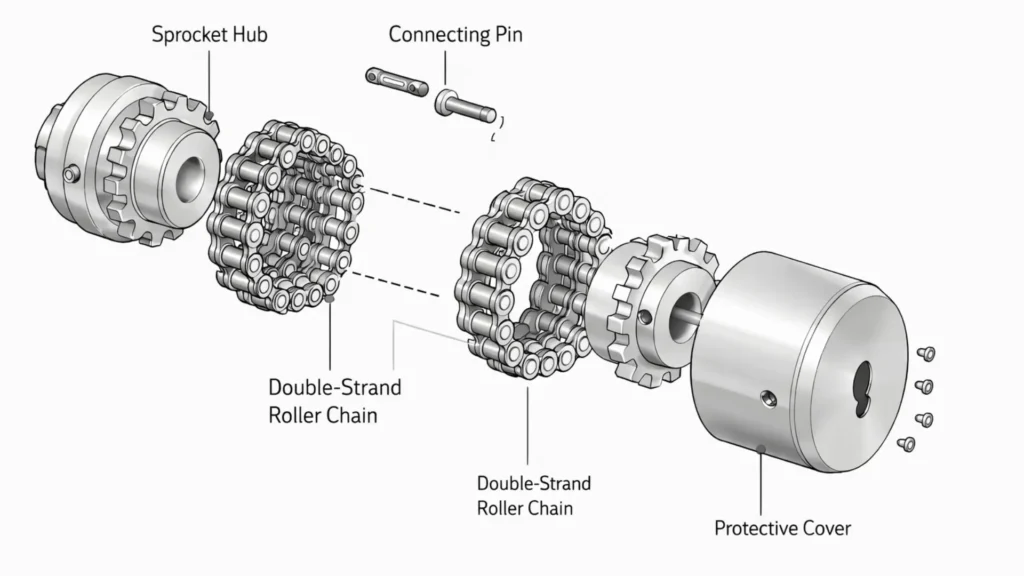

The design is deceptively simple but highly effective. A standard chain coupling consists of three main components:

- Sprocket Hubs: Two hardened steel sprockets, one attached to each shaft

- Roller Chain: A length of double-strand roller chain that wraps around the two sprockets, connecting them.

- Connecting Pin: A pin that secures the chain in place, allowing for easy assembly and disassembly.

- Protective Cover (Optional): An aluminum or plastic casing that holds lubricant and protects the coupling from dust, debris, and moisture.

While rigid couplings lock shafts together with zero flexibility, chain couplings provide the necessary “give” to prevent shaft damage during operation.

Why Chain Couplings Are Used in Industrial Applications

Industrial environments are rarely perfect. Shafts shift, vibrations occur, and shock loads can spike unexpectedly. Chain couplings are the go-to choice for engineers and facility managers because they are built to withstand these realities.

One of the primary reasons for their widespread use is their ability to transmit high torque. Because the load is distributed across multiple sprocket teeth and chain links, these couplings can handle significant power transfer without slipping or failing. Additionally, they are excellent at absorbing shock loads, which protects expensive motor bearings and equipment from damage.

Cost is another significant factor. Compared to complex gear couplings, chain couplings are often more cost-effective to purchase and maintain, making them a durable solution for budget-conscious operations.

Key Advantages of Chain Couplings

Choosing a chain coupling offers distinct operational benefits:

- High Torque Capacity: They offer one of the highest torque-to-size ratios available, meaning you get powerful performance from a compact unit.

- Misalignment Handling: They can handle angular (up to 2 degrees), parallel, and axial misalignment, reducing stress on connected equipment.

- Easy Installation: You do not need to move the driver or driven equipment to install or remove the chain. Simply wrap the chain around the sprockets and insert the connecting pin.

- Low Maintenance: Aside from periodic lubrication, they require very little attention.

- Minimal Backlash: When properly tensioned, they offer minimal backlash, ensuring precise power transmission.

Start Your Journey With Us – Enquire Now

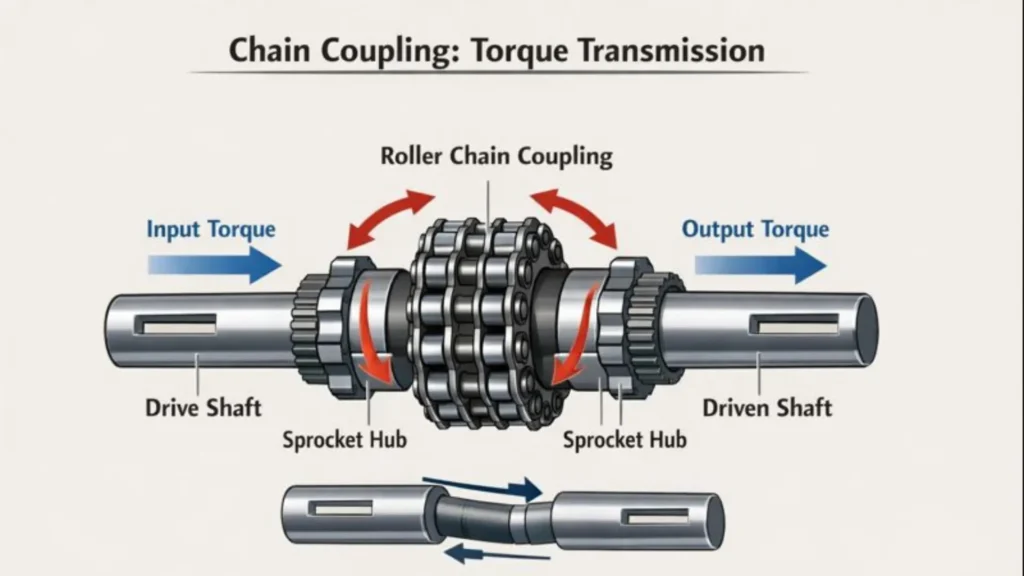

How Chain Couplings Work

The mechanics of a chain coupling rely on the interaction between the chain and the sprocket teeth. When the driving shaft rotates, the attached sprocket turns. The double-strand roller chain, which is engaged with the teeth of both sprockets, pulls the driven sprocket, causing the second shaft to rotate.

Because the connection is made via a chain rather than a rigid flange, there is inherent clearance between the chain rollers and sprocket teeth. This clearance allows the coupling to flex slightly, compensating for minor misalignment without losing the connection.

Types of Chain Couplings Available

Depending on your specific application, different variations are available:

- Standard Roller Chain Coupling: The most common type, utilizing standard double-strand chain.

- Heavy-Duty Chain Coupling: Built with thicker side plates and hardened pins for extreme torque applications.

- Enclosed / Covered Chain Coupling: Features a gasketed cover to retain grease and exclude contaminants, significantly extending service life.

- Custom Chain Coupling Solutions: Tailored bore sizes and keyways for unique machinery requirements.

Chain Coupling vs Other Coupling Types

How does a chain coupling stack up against the competition?

Chain Coupling vs Gear Coupling

Gear couplings can generally handle higher torque densities and higher speeds than chain couplings. However, gear couplings are significantly more expensive, require more intensive lubrication, and are more difficult to install. For most medium-to-heavy industrial applications, chain couplings offer a better balance of performance and cost.

Chain Coupling vs Jaw Coupling

Jaw couplings are excellent for dampening vibration and are quiet, but they typically cannot handle the same torque levels as chain couplings. If your application involves heavy loads, a chain coupling is the superior choice.

Chain Coupling vs Rigid Coupling

Rigid couplings are simple and cheap but offer zero flexibility. If your shafts are not perfectly aligned (which is common), a rigid coupling will cause rapid bearing failure. Chain couplings forgive these imperfections.

Design & Engineering Considerations

Selecting the right coupling requires evaluating several factors:

- Shaft Diameter: Ensure the bore size matches your driving and driven shafts.

- Torque and Speed: Verify that the coupling is rated for your motor’s horsepower and RPM.

- Environment: For dusty or wet environments, a protective cover is mandatory.

- Safety Factor: Always apply a safety factor (service factor) based on the type of load (uniform, moderate shock, or heavy shock).

Installation & Maintenance Guide

Installation

- Mount the Sprockets: Slide the sprocket hubs onto the shafts. Ensure the faces of the sprockets are flush with the shaft ends unless otherwise specified.

- Align the Shafts: Bring the shafts together. Use a straight edge to check parallel alignment and calipers to check angular alignment. The gap between sprocket faces should be set according to the manufacturer’s specifications.

- Install the Chain: Wrap the double-strand chain around the sprockets.

- Secure: Insert the connecting pin and secure it with the cotter pin or spring clip.

- Lubricate: Apply grease to the chain. If using a cover, install it now and fill it with grease.

Maintenance

- Lubrication: Check grease levels weekly for high-speed applications or monthly for standard use.

- Inspection: Look for signs of wear on sprocket teeth or chain elongation.

- Replacement: If the chain is worn but sprockets are good, you can often replace just the chain, saving money.

Common Problems & Troubleshooting

- Excessive Vibration: usually indicates severe misalignment or a loose set screw. Re-check alignment immediately.

- Chain Wear: Rapid wear suggests a lack of lubrication or abrasive contaminants. Install a cover.

- Noise: A loud clattering noise often means the chain is hitting the cover or the shafts are hitting each other due to a lack of gap spacing.

- Premature Failure: This is often caused by overloading. Ensure the service factor was calculated correctly for shock loads.

Technical Specifications

While specifics vary by model, general capabilities include:

- Torque Capacity: Can range from moderate (looping conveyors) to extreme (rock crushers).

- Max RPM: Typically lower than jaw or gear couplings; usually limited to 5000 RPM for smaller sizes and lower for larger sizes.

- Bore Sizes: Available in a wide range of imperial and metric sizes.

- Material: Sintered iron (for light duty) or carbon steel (for heavy duty).

Industries & Applications

You will find these workhorses in virtually every heavy industry:

- Conveyor Systems: Transferring power to drive rollers.

- Mining: Crushers and vibrating screens.

- Agriculture: Harvesters and grain augers.

- Manufacturing: Textile machinery and steel rolling mills.

- Material Handling: Palletizers and packaging lines.

Chain Coupling Supplier Based in Toledo, Ohio

Location matters when downtime is costing you money. Ohio Roller Chain is proudly based in Toledo, Ohio. Our strategic location enables faster response times and dependable local support. We leverage efficient shipping routes to serve both regional and nationwide customers with speed and reliability. When you call us, you are speaking to experts who understand American industry.

Compliance & Quality Standards

We take quality seriously. Our couplings meet ANSI and ISO compliance standards, ensuring they interchange perfectly with other standard components. We maintain strict quality control processes and material traceability so you can trust the parts you install.

Why Choose Ohio Roller Chain?

- Proven Expertise: We know power transmission inside and out.

- Quality Focused: We use premium steel and precision manufacturing.

- Customer Support: Responsive technical support to help you size and select the right part.

- Inventory: A wide range of standard and custom solutions ready to ship.

FAQs

What is a chain coupling used for?

It is used to connect two shafts to transmit torque while accommodating slight misalignment in industrial machinery.

How much misalignment can a chain coupling handle?

Most can handle angular misalignment up to 1 or 2 degrees and parallel misalignment of roughly 2% of the chain pitch, though this varies by manufacturer.

How often should a chain coupling be lubricated?

For open couplings, lubricate weekly. For covered couplings, check grease levels monthly and replenish as needed.

Are chain couplings suitable for high-speed applications?

Generally, no. They are best suited for low-to-medium speed applications. High speeds can cause the lubricant to fling off and the chain to wear prematurely.

What industries commonly use chain couplings?

They are widely used in mining, agriculture, steel manufacturing, and general material handling.

Get Your Equipment Moving

Don’t let a failed connection stop your production line. Trust Ohio Roller Chain for durable, high-performance chain couplings that stand up to the toughest conditions.

Need a quote or technical advice?