Roller Chain Coupling – Complete Guide

In today’s industrial world, every machine depends on stable and efficient power transfer. Whether you run a manufacturing setup, conveyor system, food-processing unit, agricultural plant, or a heavy-duty mining operation, your machinery needs a coupling that can handle load, vibration, and misalignment effortlessly. That’s where a roller chain coupling becomes one of the most reliable tools in your entire system.

This guide explains what roller chain couplings are, how they work, where they are used, how to install them, and how to maintain them. It’s designed in short, mobile-friendly paragraphs so anyone can read it quickly and clearly.

What Is a Roller Chain Coupling?

A roller chain coupling connects two rotating shafts and transfers torque from one shaft to another. Instead of requiring perfect alignment like rigid couplings, it can handle small misalignments while still providing strong, reliable performance.

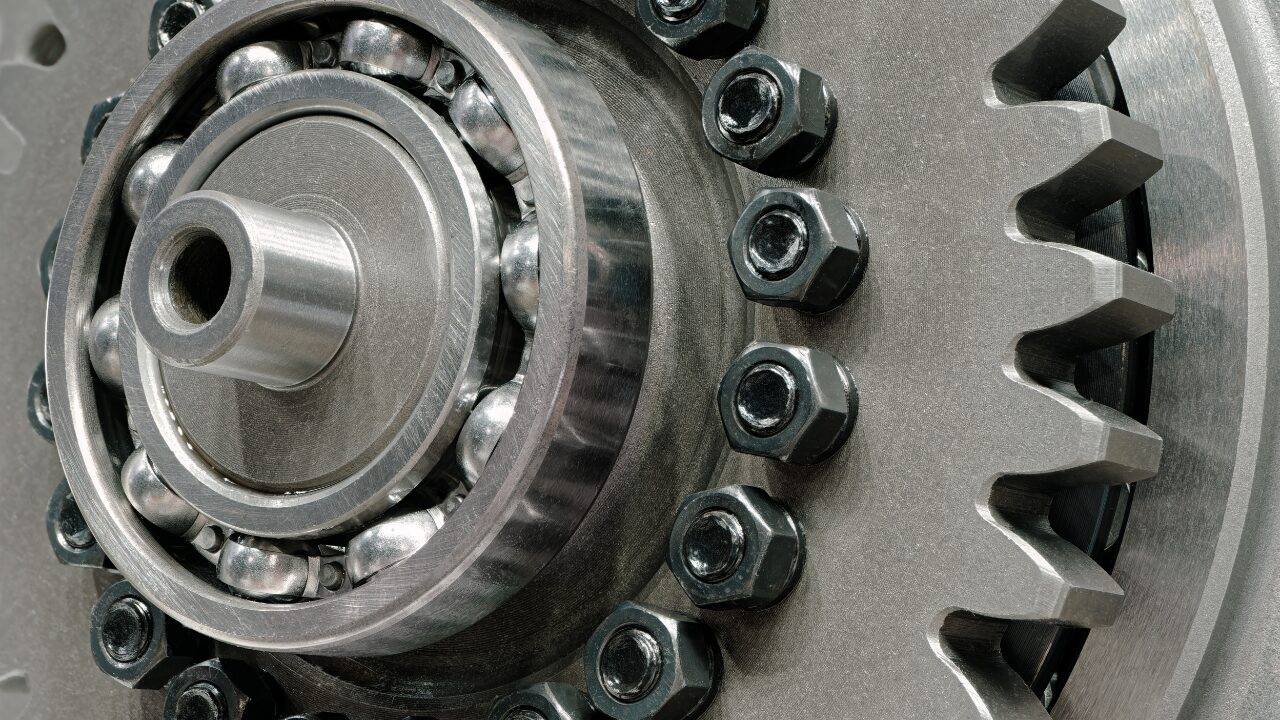

It consists of two sprockets mounted on separate shafts and a roller chain wrapped around them. When the driving shaft rotates, the chain moves the driven shaft smoothly and efficiently.

Why the Construction Is So Effective

The design of a roller chain coupling is simple but extremely dependable. Each sprocket is machined to match the chain pitch, ensuring the chain fits perfectly. Once the chain is wrapped and secured, it forms a strong mechanical link between both shafts.

A protective cover is sometimes added to keep dust out and maintain lubrication. This improves safety and increases the lifespan of the coupling.

The best part about this construction is that it spreads torque evenly across the entire chain. This reduces stress and prevents unnecessary wear. It’s one of the reasons these couplings have such long service life even in tough conditions.

Where Roller Chain Couplings Are Used

Roller chain couplings are found across many industries because they perform well in environments where dust, moisture, shock load, and vibration are common.

Manufacturing plants use them on mixers, conveyors, packaging machines, and material-handling equipment. Food-processing factories use them on roller conveyors, filling lines, and washing systems because they don’t slip and can handle wet environments.

In mining and construction, they run crushers, screeners, and heavy conveyors. Agriculture, including grain handling and feed processing, also depends on them due to their durability and easy maintenance.

Their ability to work consistently in difficult conditions makes them a top choice across different sectors.

How a Roller Chain Coupling Works

The working principle is simple: the driving shaft rotates its sprocket, the chain transfers the motion to the second sprocket, and both shafts rotate together. The chain allows a small amount of flexibility, so the coupling can handle vibration, shock, and slight misalignment without losing efficiency.

This flexibility is why the coupling performs better than rigid designs in many industrial setups.

How to Install a Roller Chain Coupling

Installing a roller chain coupling is easier than installing many other types of couplings. Start by preparing the shafts. Make sure they are clean, straight, and free from rust or dirt. This prevents unnecessary friction and wear.

Slide each sprocket onto its shaft and position them so they face each other. Secure them using the set screws or keyway provided. Proper alignment is essential here, so using a straightedge or alignment tool is helpful.

Next, wrap the roller chain around both sprockets. Insert the connecting link and lock it into place. Before tightening everything, rotate the shafts manually to check for smooth movement. If there is any resistance, realign the sprockets.

If your application uses a coupling cover, install it last. It protects the chain from contaminants and helps retain lubrication.

Why Industries Prefer Roller Chain Couplings

There are several reasons why these couplings are widely used. They offer excellent power transmission efficiency, often above 96%, which means very little energy is lost during operation. Their ability to absorb shock loads protects sensitive machine parts from sudden stress.

They also perform extremely well in harsh conditions. Dirt, dust, and moisture do not significantly affect performance, making them ideal for outdoor or high-load environments.

Another major advantage is their ability to handle misalignment. Many machines naturally shift or vibrate during operation. Roller chain couplings can accommodate angular, radial, and axial misalignment without failing.

Companies also appreciate how easy they are to install, inspect, and replace. You don’t need special tools or lengthy downtime, which is important when productivity matters.

Maintenance Tips for Long-Term Performance

Like any mechanical component, roller chain couplings perform best with regular maintenance. Lubrication is important unless you’re using a lubrication-free model. Oiling reduces friction and prevents chain wear.

Check chain tension regularly. A chain that’s too tight adds stress to the sprockets. One that’s too loose causes slipping or jerking.

Examine the sprocket teeth for signs of wear or bending. If the teeth become damaged, the chain will not move smoothly. Also watch for chain elongation over time; chains naturally stretch due to use, and replacing them when they become too long prevents further damage.

Keeping the coupling clean also helps extend its lifespan, especially in dusty environments.

Choosing the Right Roller Chain Coupling

Selecting the correct coupling begins with understanding the operating environment. Machines exposed to dirt, moisture, chemicals, or high temperatures need specific materials or covers to ensure long-lasting performance.

You should also consider speed and torque requirements. The coupling must match your machine’s horsepower and RPM rating.

Shaft diameter and bore size must also be compatible. A mismatch here can cause vibration and premature wear.

The degree of misalignment expected during operation is another factor. Applications with higher misalignment may benefit from a double-strand chain coupling, which offers greater strength and flexibility.

If your facility requires strict safety or cleanliness standards, a protective cover may be essential.

By evaluating all these factors, you can select a roller chain coupling that ensures smooth, long-lasting, and trouble-free performance.

Frequently Asked Questions

What is a chain coupling?

A chain coupling uses two sprockets and a roller chain to connect two shafts and transfer torque efficiently.

How does it work?

The driving sprocket rotates the chain, which moves the second sprocket and drives the other shaft.

Do chain couplers need lubrication?

Most do, although low-maintenance options are available.

Can roller chain couplings handle misalignment?

Yes, they are built to handle angular, radial, and axial misalignment.

Are double-strand chain couplings stronger?

Yes, they offer higher torque capacity and increased durability.

Conclusion

A roller chain coupling is a dependable, durable, and efficient solution for connecting machinery and ensuring smooth torque transmission. Its simple construction, long service life, and ability to handle misalignment make it an essential component in many industrial setups. With the right selection and proper maintenance, your system can achieve long-lasting performance with minimal downtime.

If you’re looking for a stronger and more durable option for heavy-duty equipment, explore our double roller chain coupling, designed for maximum strength and long-term reliability.