Industrial Chains: Complete Guide to Types & Applications

An industrial chain is a critical component used in almost every industry—from manufacturing and automation to agriculture and heavy machinery. If you’ve ever seen equipment lifting loads, conveying materials, or transferring power, an industrial chain is often the part making it possible. But with so many chain types, materials, sizes, and applications, choosing the right chain can feel overwhelming.

That’s why this blog is designed as a complete, easy-to-understand guide for beginners, technicians, and industry professionals. By the end, you’ll have full knowledge of industrial chains and roller chains—including how they work, the different types available, where each type is used, and how to select the right one for your machinery. You’ll also learn about roller chain sizes, stainless steel roller chains, industry chains, maintenance tips, and common problems to watch out for.

Whether you’re buying a chain, maintaining equipment, or simply expanding your technical understanding, this blog gives you everything you need to know in one place.

What Is an Industrial Chain?

An industrial chain is a mechanical component designed to transmit power, move materials, or support lifting operations in industrial machinery. It is built from interconnected metal links that work together to create a strong, flexible, and durable system capable of handling heavy loads and continuous motion.

At its core, an industrial chain works by engaging with sprockets to transfer rotational motion or to pull, lift, or convey objects from one point to another. Because of this simple yet powerful mechanism, industrial chains are widely used in industries like manufacturing, packaging, agriculture, mining, food processing, automotive, and material handling.

Key Components of an Industrial Chain

Inner & Outer Plates: Provide structural strength.

Pins: Hold the chain plates together.

Bushings: Create a smooth surface for the rollers to rotate on.

Rollers: Reduce friction and allow smooth engagement with sprockets.

These components work together to deliver high strength, consistent performance, and long operating life, even in harsh industrial environments.

Industrial chains are preferred in many systems because they offer:

High load-carrying capacity

Precise power transmission

Compatibility with varying speeds and harsh conditions

Long-term durability with proper maintenance

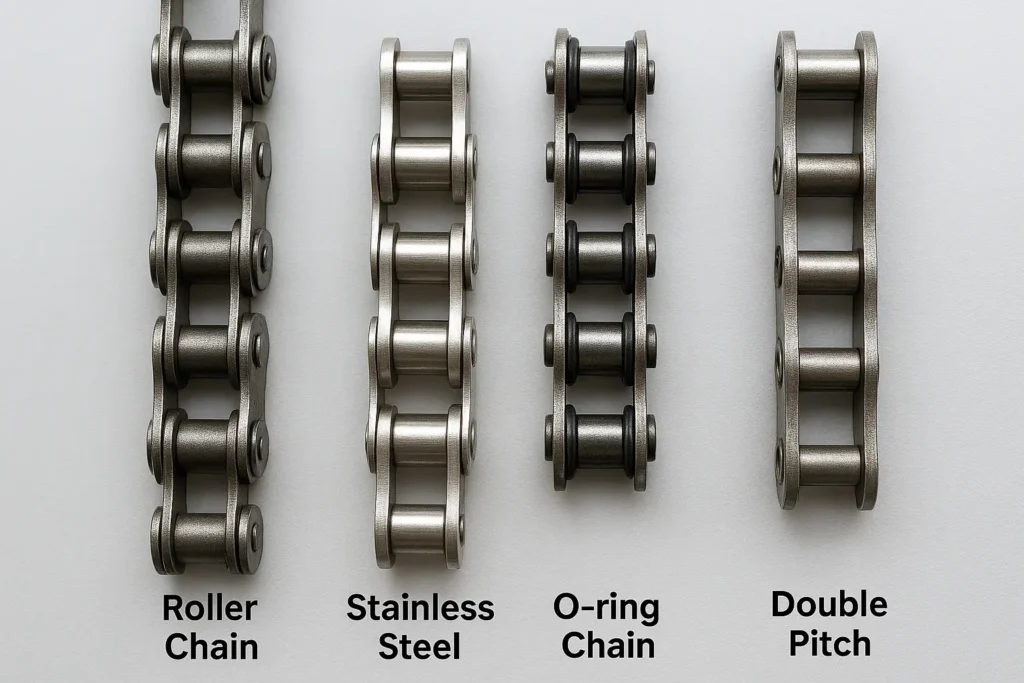

Types of Roller Chains

Roller chains come in various designs to match different industrial needs, load requirements, and operating environments. Below are the 5 most common and essential types of roller chains used across industries.

1. Standard Roller Chain (ANSI/ISO)

This is the most widely used roller chain in industrial machinery and power transmission systems.

Features:

Available in various roller chain sizes

High strength and reliable performance

Uses: Manufacturing equipment, conveyors, motors, packaging machines

2. Heavy-Duty Roller Chain

Built with thicker plates and higher tensile strength to handle tougher conditions.

Features:

Designed for heavy loads and shock resistance

Suitable for continuous, high-stress operations

Uses: Mining, construction machinery, high-load conveyors

3. Stainless Steel Roller Chain

Made from corrosion-resistant stainless steel for clean or harsh environments.

Features:

Rust-proof

Hygienic and chemical-resistant

Uses: Food processing, pharmaceutical, outdoor equipment, washdown environments

4. Double Pitch Roller Chain

Has longer pitch length for lighter, slower-speed applications.

Features:

Cost-effective

Ideal for long conveyor systems

Uses: Agricultural equipment, long conveying lines, light-duty machinery

5. O-Ring / X-Ring Roller Chain

Equipped with sealed rings between the plates to retain lubricant.

Features:

Long service life

Low maintenance

Uses: Motorcycles, outdoor machines, dusty or high-friction environments

Materials Used in Industrial Chains

The performance, durability, and lifespan of an industrial chain depend heavily on the material it is made from. Different environments—such as high moisture, chemicals, extreme loads, or high temperatures—require specific chain materials to ensure reliable operation.

Below are the most common materials used in industrial chains and why they matter:

1. Carbon Steel

Carbon steel is the standard and most widely used material for industrial chains.

Benefits:

High strength and durability

Cost-effective

Ideal for general machinery

Best For: Manufacturing, conveyors, packaging systems

2. Alloy Steel

Alloy steel chains are heat-treated and designed for heavy-duty performance.

Benefits:

Excellent wear resistance

High tensile strength

Handles shock loads well

Best For: Mining, construction, high-impact equipment

3. Stainless Steel

Stainless steel chains are made for corrosion resistance and hygienic environments.

Benefits:

Rust-proof

Chemical-resistant

Easy to clean

Best For: Food processing, pharmaceuticals, outdoor equipment

(Uses your secondary keyword: stainless steel roller chain)

4. Nickel-Plated Steel

Nickel-plated chains offer a balance between corrosion resistance and affordability.

Benefits:

Protects against moisture

Improves appearance

Resists mild chemicals

Best For: Packaging machines, light outdoor use, humid areas

5. Plastic / Polymer Chains

Used in applications where low noise, lightweight, and corrosion resistance are essential.

Benefits:

Quiet operation

Non-metallic and spark-free

Resistant to chemicals

Best For: Electronics, food handling, light-duty conveyors

How to Select the Right Industrial Chain

Choosing the right industrial chain is crucial for smooth operation, safety, and long-lasting performance. Start by considering the load and strength the chain needs to handle. Think about maximum weight, continuous or intermittent use, and whether it will face sudden shock loads.

Next, consider speed and operating conditions. High-speed machinery may require precision roller chains, while harsh environments with dust, moisture, chemicals, or extreme temperatures affect the choice of material. Chain size and pitch must also match your sprockets and equipment for proper performance.

Material selection is very important. Carbon steel chains are ideal for general industrial use, alloy steel chains handle heavy-duty loads, and stainless steel roller chains resist rust and corrosion in food, pharma, and outdoor applications. Chains with O-rings or X-rings can retain lubrication and reduce wear, extending their service life.

Finally, think about maintenance and special needs. Consider how often the chain will be inspected or replaced, and if you need quiet operation, chemical resistance, or high precision. By keeping these factors in mind, you can choose an industrial chain that is reliable, efficient, and long-lasting.

Maintenance & Care of Industrial Chains

Keeping your industrial chains in top condition is simple if you follow these key steps:

Regular Inspection

Check for wear, loose links, broken pins, or corrosion.

Identify problems early to avoid costly downtime.

Proper Lubrication

Apply the right lubricant to reduce friction and prevent rust.

O-ring or X-ring chains hold lubrication longer, reducing maintenance.

Tension Adjustment

Ensure chains are neither too loose nor too tight.

Proper tension prevents slipping, uneven wear, and stress on links.

Cleaning

Remove dirt, dust, and chemical buildup regularly.

Use suitable cleaning solutions to avoid damaging the chain.

Monitor Usage Environment

Chains in dusty, wet, or corrosive environments need extra care.

Adjust maintenance frequency based on operating conditions.

Industrial Chain vs Other Power Transmission Systems

Industrial chains are strong, durable, and ideal for high-load power transmission. They work reliably in harsh, dusty, or wet environments where other systems might fail.

Compared to belts, chains don’t slip and provide more precise motion. Belts are quieter and lighter but may stretch over time and are less suitable for heavy loads.

Shaft-driven systems are durable but often more complex and costly to install. Chains are flexible, cost-effective, and reliable, making them the preferred choice for heavy-duty and high-precision industrial machinery.

Future Trends in Industrial Chains

The industrial chain industry is evolving with new technologies and materials to improve performance and durability. Advanced coatings and heat-treated materials are making chains more resistant to wear, corrosion, and extreme temperatures.

Smart monitoring systems are also being introduced, allowing operators to track chain performance, detect wear, and schedule maintenance before problems occur. This reduces downtime and extends the chain’s lifespan.

In addition, high-efficiency designs are becoming more popular, helping industries save energy and reduce operational costs. Lightweight materials, low-friction coatings, and precision-engineered components are shaping the next generation of industrial chains for more sustainable and reliable operations.

Conclusion

Industrial chains are the backbone of modern machinery, providing reliable power transmission, material handling, and lifting solutions across industries. Understanding the different types, materials, applications, and maintenance needs helps you choose the right chain for your equipment.

Whether it’s roller chains, stainless steel chains, or specialty chains, selecting the right type and maintaining it properly ensures long-lasting performance and reduces downtime.

Ready to upgrade your machinery with high-quality industrial chains? Explore our range of durable, efficient chains today and ensure smooth, reliable operation for all your industrial applications.