Types of Sprockets – Uses, Maintenance & Key Benefits

From bicycles to massive industrial conveyors, the humble sprocket plays a critical role in keeping the world moving. While often overshadowed by flashier machinery components, sprockets are the unsung heroes of power transmission, ensuring energy moves efficiently from one point to another.

In mechanical systems, efficiency is everything. A sprocket with chain system provides a reliable, non-slip method of transmitting rotary motion between two shafts. Unlike belt drives, which can slip under heavy loads, sprockets engage directly with chain links to deliver consistent torque. This reliability makes industrial chains and sprockets indispensable across sectors like manufacturing, agriculture, and automotive engineering.

At Ohiorollerchain, we understand that the right component can make or break a system. As a supplier of quality sprockets, we know that selecting the correct type, material, and size is vital for operational longevity. This guide explores everything you need to know to make an informed choice.

What Is a Sprocket and How Does It Work?

A sprocket is a profiled wheel with teeth that mesh with a chain, track, or other perforated material. It is distinct from a gear because sprockets never mesh directly with each other; they are always separated by a chain or a belt.

So, how do chain sprockets actually work? The concept is simple but effective. As the sprocket rotates, its teeth engage the rollers or links of a chain. This engagement pulls the chain, transferring mechanical power from a driving shaft (like a motor) to a driven shaft (like a conveyor belt drum). The design of the teeth—specifically their pitch and profile—must match the chain perfectly to ensure smooth operation.

Benefits of Sprockets in Power Transmission

Why choose a sprocket system over gears or belts?

- No Slippage: The interlocking teeth provide positive engagement, ensuring precise timing and power transfer.

- High Torque: They can handle significantly higher torque loads than belt drives.

- Durability: Metal sprockets are robust and can withstand harsh environments better than rubber belts.

- Versatility: They work effectively over long center distances where gears would be impractical.

Types of Sprockets

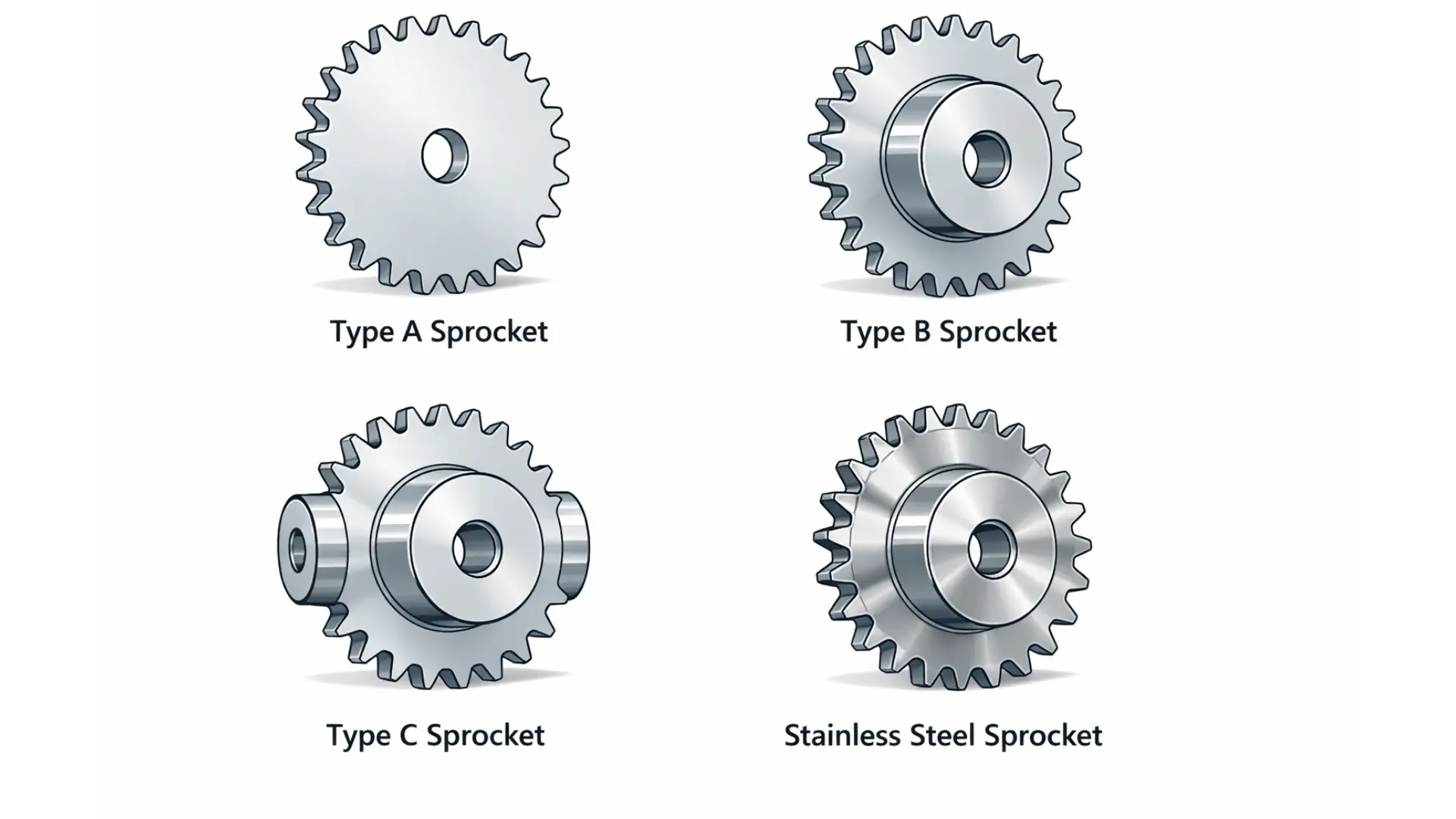

Selecting the right sprocket starts with understanding the different classifications available. The industry categorizes these components based on their hub style and intended application.

Type A Sprockets

Type A sprockets are flat, plate-like wheels with no hubs on either side. These are typically mounted on flanges or hubs that are bolted to the equipment. Because they lack a built-in hub, they are often used in applications where space is tight or where the sprocket needs to be welded directly onto a shaft or drum. Their simplicity makes them a cost-effective choice for many industrial systems.

Type B and Other Common Sprocket Types

While Type A is flat, other types incorporate hubs for better stability on shafts:

- Type B Sprockets: These feature a hub on one side. This is the most common configuration, offering a good balance of stability and space efficiency.

- Type C Sprockets: These have hubs on both sides of the plate. They are used for heavy-duty applications where maximum stability and surface contact with the shaft are required.

- Type D Sprockets: These usually have a detachable bolt-on hub, allowing for easy replacement without removing the entire assembly.

Chain Sprockets for Industrial Use

Industrial environments demand robust solutions. Chain sprockets designed for these settings are engineered to handle high speeds, shock loads, and continuous operation. They are often hardened to resist wear and are critical for heavy machinery, such as rock crushers or assembly line conveyors.

Custom and Special Sprockets

Sometimes, standard off-the-shelf parts just won’t fit. Custom sprockets can be engineered with specific tooth counts, bore sizes, or mounting options. Examples include offset sprockets, which help align chains in tight spaces, or split sprockets, which can be installed on a shaft without dismantling the entire machine setup.

Sprocket with Chain – Why Compatibility Matters

You cannot simply grab any chain and pair it with any sprocket. The golden rule of mechanical drive systems is pitch compatibility. The “pitch” is the distance between the centers of two adjacent chain rollers.

If you attempt to run a chain on a sprocket with a different pitch, the system will fail. Improper matching leads to:

- Accelerated Wear: The chain will ride up on the teeth, grinding down the metal rapidly.

- Vibration and Noise: A mismatched system runs roughly, damaging bearings and other components.

- Catastrophic Failure: Under load, the chain can jump off the sprocket or snap entirely.

Using compatible chain sprockets ensures that the load is distributed evenly across the teeth. This maximizes the lifespan of both the chain and the sprocket, resulting in smoother operation and reduced downtime.

Materials Used in Sprockets

The environment in which your machinery operates dictates the material you should choose.

Steel Sprockets

For general industrial applications, carbon steel is the standard. Steel sprockets offer excellent tensile strength and durability. They are often heat-treated to harden the teeth, which significantly increases resistance to wear over time. Whether used in automotive timing systems or factory automation, steel provides the toughness needed for high-torque situations.

Stainless Steel Sprockets

When corrosion is a concern, steel isn’t enough. Sprockets stainless steel are essential for:

- Food Processing: They resist rust and can withstand harsh wash-down procedures involving caustic chemicals.

- Chemical Industries: They offer resistance to acidic or alkaline environments.

- Outdoor Applications: They do not rust when exposed to rain or humidity.

While stainless steel is generally softer than hardened carbon steel, its longevity in corrosive environments makes it the superior choice for specific industries.

Applications of Sprockets

Sprockets are ubiquitous across almost every major industry.

- Manufacturing: They drive the conveyor belts that move products through assembly lines.

- Agriculture: From combine harvesters to seeders, sprockets transfer power to moving parts in dusty, dirty conditions.

- Automotive: Timing chains in internal combustion engines rely on high-precision sprockets to keep valves and pistons in perfect sync.

- Material Handling: Forklifts and cranes use heavy-duty chain and sprocket assemblies to lift massive weights safely.

How to Choose the Right Sprocket

Selecting the right component involves more than just picking the right number of teeth. Consider these four factors:

- Load and Torque: Heavier loads require stronger materials (like hardened steel) and potentially larger pitch sizes (like Type C hubs).

- Operating Speed: High-speed applications require precision-machined sprockets to reduce vibration.

- Chain Compatibility: Always match the sprocket pitch (e.g., ANSI #40, #60) to your chain.

- Environmental Conditions: If the machine operates in a wet or sanitary environment, opt for stainless steel or plastic composite sprockets.

Maintenance Tips for Sprockets

Even the highest quality industrial chains and sprockets require maintenance to perform their best.

- Lubrication: A dry chain destroys sprockets. Ensure your system is regularly lubricated with the correct oil or grease to reduce friction.

- Alignment: Check that the driving and driven sprockets are perfectly aligned. Misalignment causes side-wear on the teeth.

- Wear Inspection: Look for “hooked” teeth. As a sprocket wears, the teeth become sharp and hooked-shaped. If you see this, it is time to replace the sprocket to save the chain.

- Tensioning: A loose chain can slap and wear out sprocket teeth prematurely. Check tension regularly.

Why Choose Ohiorollerchain for Sprockets

At [Your Brand Name], we don’t just sell parts; we provide power transmission solutions. We pride ourselves on supplying a comprehensive range of high-quality sprockets and chain sprockets to keep your business moving.

Whether you need a simple Type A sprocket for a prototype or a fleet of stainless steel sprockets for a food processing plant, our inventory is stocked to meet your needs. Our commitment to precision manufacturing and strict quality control means you get components that fit perfectly and last longer.

Plus, our team of experts is ready to support you in selecting the right sprocket type for your specific application, ensuring you get the best performance for your investment.

Contact [Your Brand Name] to find the right sprocket solution for your machinery.

Reliable Motion Starts Here

Selecting the right sprocket is about understanding the demands of your machinery. From ensuring compatibility with your chain to selecting the right material for your environment, these decisions directly impact your operational efficiency.

By prioritizing quality components and adhering to proper maintenance schedules, you ensure that your industrial chains and sprockets systems deliver consistent power year after year. As a trusted source for industrial power transmission, Ohiorollerchain is here to help you keep the gears—and sprockets—turning.