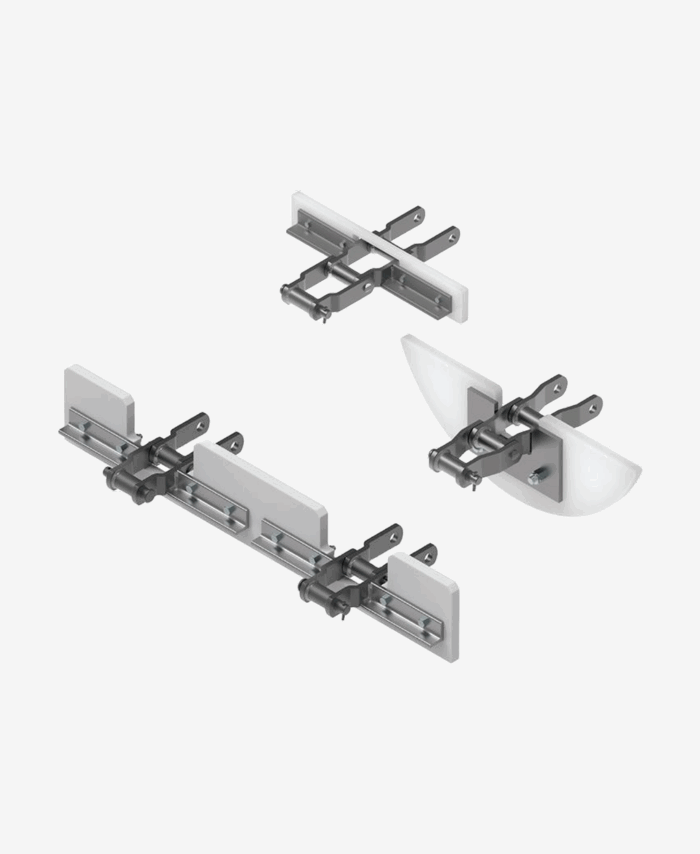

40 Double Single Sprockets

40 Double Single Sprockets are built for strength, precision, and reliable performance in power transmission. Designed for heavy-duty use, 40 Double Single Sprockets deliver durability, smooth operation, and long service life. Ideal for industrial applications, 40 Double Single Sprockets ensure efficiency.

Product Material

Care & Cleaning Instructions

Product Description

Our 40 Double Single Sprockets are engineered to run two single-strand #40 roller chains on a single sprocket, ensuring smooth and synchronized power transmission. Crafted from high-strength steel with precision-cut teeth, these Double Single Sprockets deliver long-lasting performance and reliability for demanding industrial environments.

Ideal for conveyors, packaging machinery, material handling systems, and other heavy-duty applications, they provide excellent efficiency and consistent operation. With their durable construction and precise design, these sprockets are a dependable choice for any setup requiring dual-chain operation.

Overview of Double Single Sprockets

Double Single Sprockets are specifically designed to run two single-strand roller chains side-by-side, ensuring smooth and synchronized power transmission. They are ideal for machinery and systems that require precise movement and balanced load distribution.

These sprockets are compatible with a wide range of industrial machines, from conveyors and packaging equipment to material handling systems, making them a versatile solution for heavy-duty applications.

Features of 40 Double Single Sprockets

Our 40 Double Single Sprockets are built to ANSI #40 chain standards, ensuring compatibility with standard roller chains for reliable performance.

Constructed from high-strength steel, these sprockets offer a long service life even under heavy-duty industrial conditions. The precision-cut teeth provide smooth and efficient chain engagement, reducing wear and improving overall system efficiency.

Additionally, the corrosion-resistant finish protects the sprocket from rust and environmental damage, making it suitable for a wide range of industrial applications.

Applications

These double single sprockets are widely used across various industries due to their durability and precision. They are ideal for conveyor systems and packaging machinery, ensuring smooth and synchronized operation.

They are also suitable for material handling equipment, agricultural and mechanical devices, and any machines that require dual-chain operation. Their versatility makes them a reliable choice for heavy-duty and continuous-use industrial applications.

How to Choose the Right Sprocket

Selecting the right sprocket ensures optimal performance and longevity. Start by matching the sprocket with the correct #40 double single chain type to ensure proper fit and engagement.

Next, choose the appropriate tooth count based on your system’s speed and torque requirements. Select the correct bore size and hub type to fit your shaft securely, and consider factors like working load, operating environment, and maintenance needs to ensure reliable and efficient operation.

Why We’re the Best

At Ohio Roller Chain, we use premium-grade materials and precise machining to ensure long-lasting durability and perfect chain alignment. Each sprocket is built for smooth, efficient operation, minimizing wear and maintenance requirements.

In addition to quality, Ohio Roller Chain offers competitive pricing, bulk order options, and fast shipping. Our team provides reliable technical support, and we can create custom sprockets to meet unique industrial requirements, making us a trusted choice for any application.

Demand Pricing

On make $100+

Best Built Quality

Its gurantee

On Time

Complete before deadline

Wide Collections

Options for best choice

A Reputation 25 Years in the Making